NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has expanded its series of high-load drive ball screws used by electric injection molding machines. NSK will start selling this series in January 2015 and expects global sales of 1 billion yen in 2016.

NSK exhibited this product at the International Plastic Fair Japan 2014 “IPF 2014” at Makuhari Messe (Chiba) from Tuesday, October 28 to Saturday, November 1, 2014.

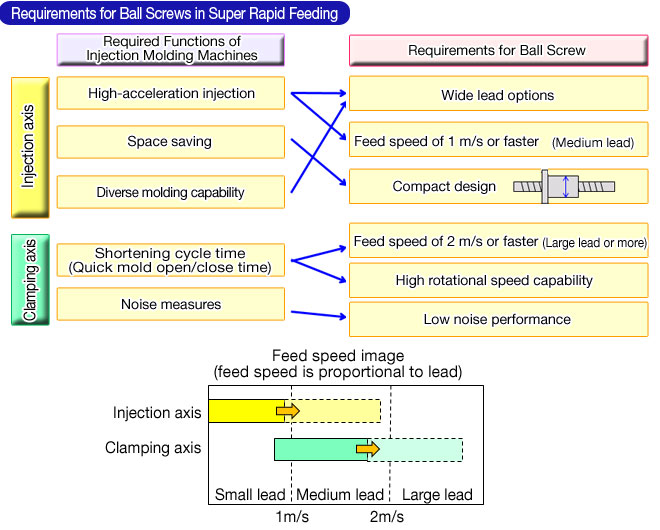

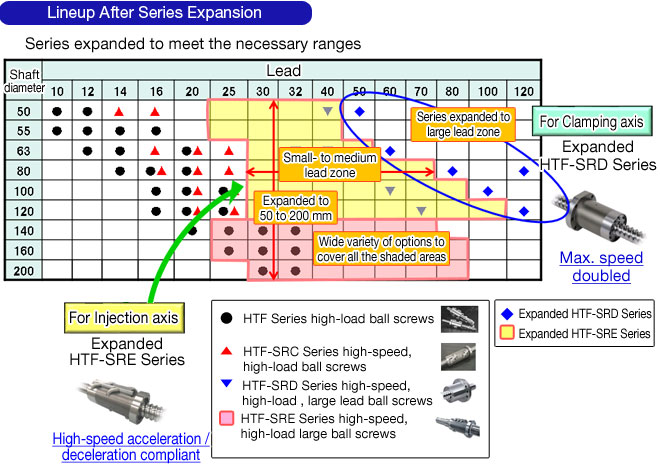

NSK's high-load drive ball screws are mainly used for the injection and clamping drive axes of electronic injection molding machines. NSK began selling these ball screws in 1996, and over time, as the needs for higher speeds, greater sizes and environmental measures have arisen, NSK has expanded this product series, which has a solid reputation for performance and quality.

In recent years, smart phones and tablets have become larger and lighter, driving the need for the light-guide plates used in the displays thereof to be thinner. As a result, it has become necessary to perform high-speed injection molding of the light-guide plates, which in turn has driven the need for the drive ball screw used in injection molding machines to provide higher acceleration and feed speeds.

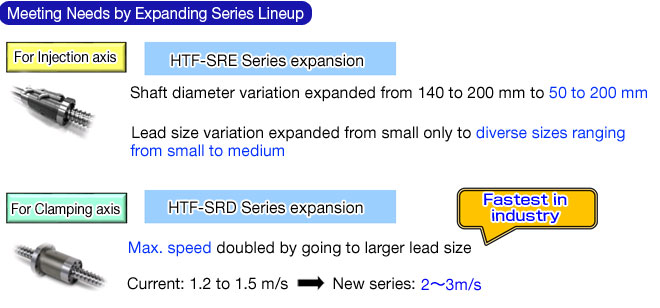

In response to these needs, NSK has improved the design and production technology of its ball screw to expand its series by adding the world's fastest high-load drive ball screws. These new ball screws will support faster acceleration and feed speeds for the drive axes of injection molding machines.