NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new retainer plate* equipped ball bearing for automobile transmissions.

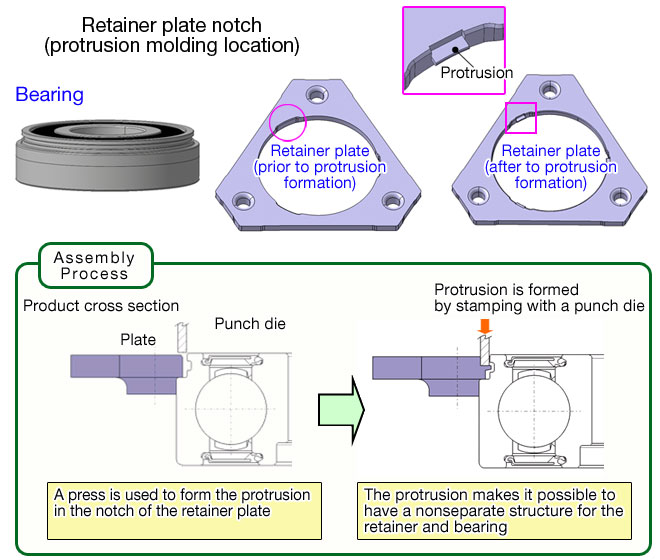

This new product can be automatically assembled thanks to a process involving the formation of a protrusion inside the retainer plate using a press machine, making it possible to fasten the retainer plate to the bearing. This new structure also makes it possible to increase engine torque and can work with a variety of plate shapes. This helps to make transmissions more compact and lighter, and it enables higher performance.

NSK is targeting 1 billion yen in global annual sales in 2018 for this product.

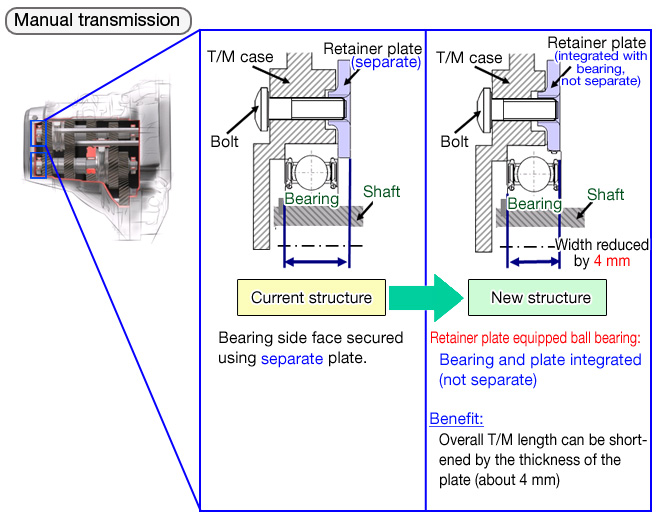

| * Retainer plate: |

A plate that secures the bearing to the housing in order to restrict axial movement of the shaft and bearing. |

Manual transmission vehicles and dual clutch transmission vehicles are becoming more popular, especially in developing countries and Europe. The bearings used in these transmissions need to have greater rigidity to help reduce the overall length of the transmission. As a result, retainer plate equipped ball bearings are increasingly being used for such applications.

NSK's previous retainer plate equipped ball bearings were assembled manually with three components -the bearing, the retainer plate and the snap ring. As such, the challenge lies in improving assembly productivity. Furthermore, due to the increased use of turbo charging, the load on these bearings has increased. Also, transmissions are getting more compact and need to be able to work with a greater variety of layouts than ever before.

In response to this situation, NSK has developed a new retainer plate equipped ball bearing that possess the following advantageous features: improved productivity, increased engine output capability and accommodates a variety of transmission layouts.

This new product helps make transmissions more compact and lighter, and it enables higher engine performance.