NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed the high-speed, low-noise Ball Screw II, which has greatly reduced peak noise during ball screw operation. NSK will start selling this product in January 2015 and expects global sales of ¥4 billion in 2016.

NSK will exhibit this product at JIMTOF 2014, the 27th Japan International Machine Tool Fair, to be held at Tokyo Big Sight (Tokyo) from Thursday, October 30 to Tuesday, November 4, 2014 and at the International Plastic Fair Japan 2014, to be held at Makuhari Messe (Chiba) from Tuesday, October 28 to Saturday, November 1, 2014.

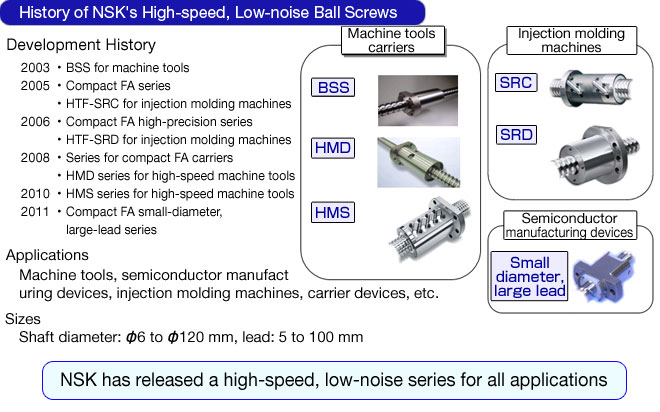

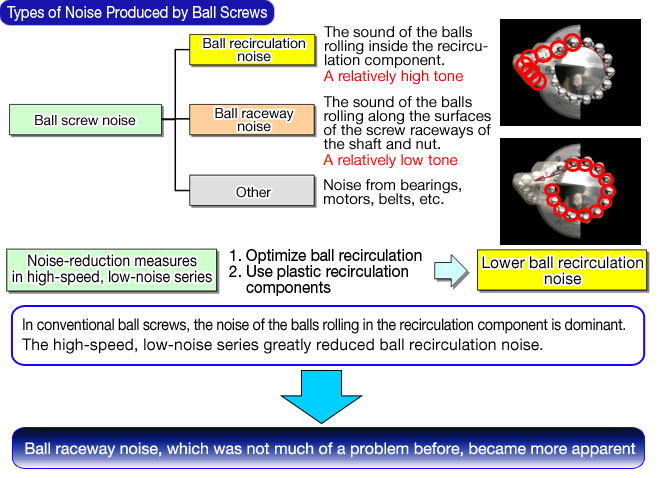

Noise during ball screw operation mainly comes from the ball recirculation portion and the ball raceway portion. Since 2003, NSK has released high-speed, low-noise ball screws with reduced ball recirculation noise for various uses, including machine tools and injection molding machines.

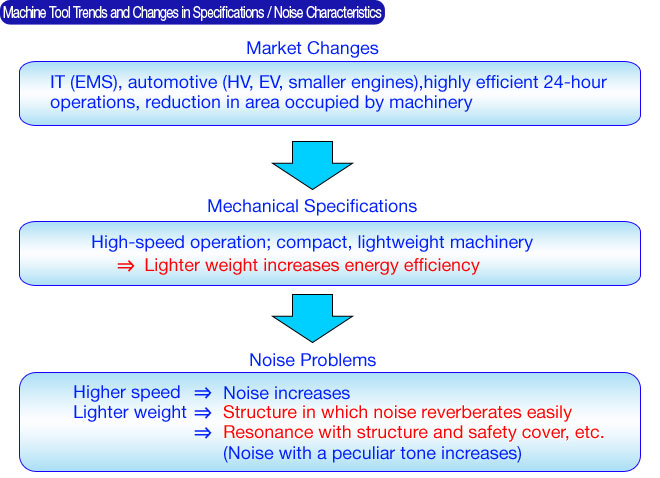

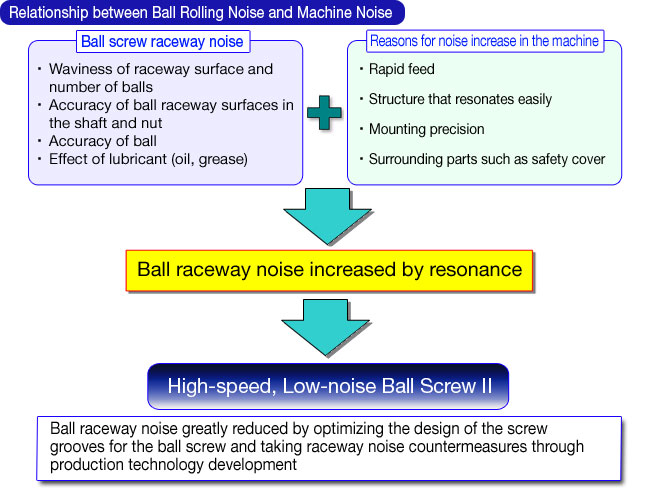

In recent years, production machinery, as typified by machine tools, has become more compact and lighter. Consequentially, there is now a need for countermeasures against resonance in the machinery caused by the ball raceway noise, which was not a problem before.

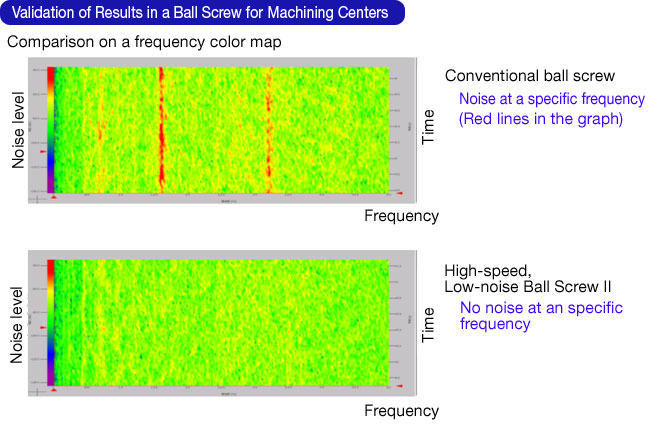

In order to meet the demand for even lower noise, NSK developed the high-speed, low-noise Ball Screw II, which greatly reduces resonance in machinery caused by ball raceway noise. This product will help improve the environment at production sites through lower noise in all manner of industrial machinery and devices, including machine tools, carrier devices, semiconductor manufacturing equipment, injection molding machines, and medical devices.