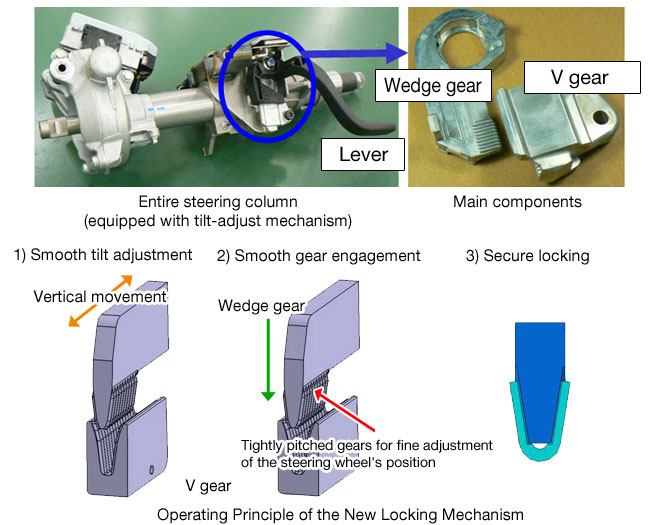

Tokyo, Japan, April 24, 2013-NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new steering-wheel locking mechanism wedge gear system for steering systems that improves the safety of occupants during automobile collisions. This product is currently applied to the Volkswagen up!, a compact car that is sold in Europe and Japan. The new mechanism is designed for application in a wide variety of car models throughout the world.

This new product is in line with NSK's never-ending goal of improving and advancing its steering technology offerings in order to meet the many demands of automotive applications, such as safety and comfort.

The steering system translates the movement of the steering wheel to the wheels (in terms of steering angle and force) as the driver turns the steering wheel to turn the vehicle in the desired direction. In addition, the steering system provides drivers with the ability adjust the steering wheel to the desired position in their vehicle.

Moreover, during collisions, the steering column is designed to collapse in order to soften its impact on the driver.

Furthermore, airbags are used in addition to seatbelts to protect occupants. In the event of a collision, airbags are deployed to prevent occupants from having direct contact between their head and chest and components such as the steering wheel. The steering column, which houses the driver's airbag, is required to sustain a strong impact, without moving up and down, as its airbag is deployed.

One example of conventional steering column locking mechanisms employ a multi-plate method that involves the layering of multiple steel plates to create friction in order to lock the steering wheel in place. However, even at the unlocked position, this method does not provide enough clearance between the steel plates. As a result, when the steering-wheel position is adjusted, multiple steel plates slide, and sometimes this can result in the steering system not always operating smoothly . In addition, due to the unstable levels of frictional force inherent in this kind of system, more and more steel plates are required to achieve the necessary locking force, which, unfortunately, means more components and more weight.

In response to these concerns, NSK has developed a new steering-wheel locking mechanism wedge gear system for automotive applications that is superior because it provides both the locking force stability needed for the steering wheel in the event of a collision and the operability for adjusting the position of the steering wheel.