Tokyo, Japan, March 18, 2013 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) announced today that it has developed a long-life sealed spherical roller bearing with improved abrasion toughness for application in heavy industries such as mining, iron and steel manufacturing and non-ferrous metals manufacturing. The improved life of this product provides customers with more stable operations and lower maintenance costs.

NSK is targeting 500 million yen a year in global sales in fiscal 2016.

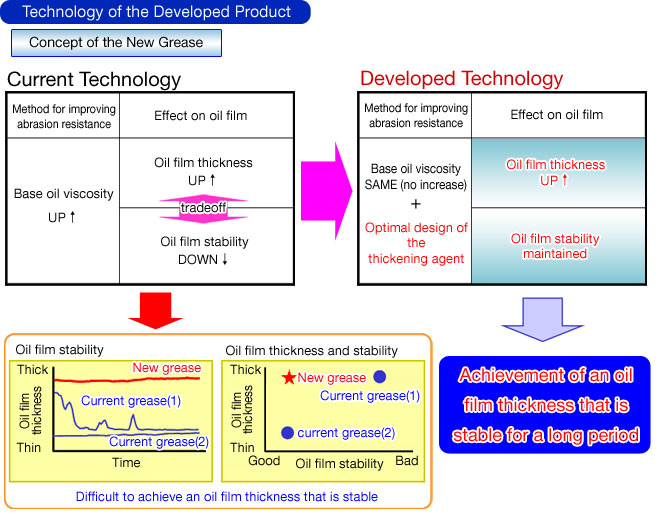

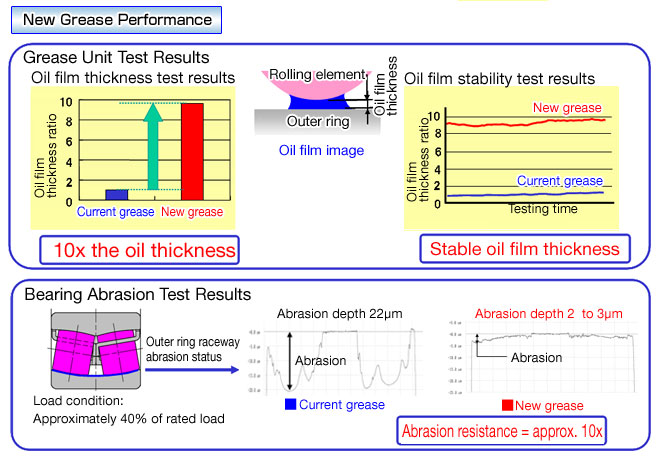

As global urbanization and population growth continues to increase, the demand in the areas of mining, iron and steel manufacturing and non-ferrous metals manufacturing continues to expand, primarily in emerging nations. The equipment used for these applications runs 24 hours a day, 365 days a year and under harsh conditions such as high temperatures, exposure to foreign substances and cooling water intrusion. Due to these conditions, sealed greased spherical roller bearings* are widely used. However, in recent years the equipment in which these bearings are used has become more compact, resulting in the downsizing of the bearings. At the same time, the capability and workload of the equipment has also increased, resulting in greater loads being exerted on the bearings, which in turn is increasing the frequency of maintenance and repairs and the cost thereof. In response to this situation, NSK has developed a long-life, sealed spherical roller bearing with improved abrasion toughness for heavy industry applications.

- * Spherical roller bearings (self-aligning roller bearings) have a high radial load capacity and, as such, are well suited to applications that undergo heavy loads and impact loads. The outer ring's raceway surface is curved so that the center of curvature is aligned to the center of the bearing. This makes it so that the inner ring, rolling element and cage can all tilt freely in relation to the outer ring, providing for self-alignment capability.

As outlined above, this product achieves longer life, which means a stable level of equipment operation and a reduction in maintenance costs.