Tokyo, Japan, March 18, 2013 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) announced today that it has developed a high-performance ball bearing for cooling fan motors used in such applications as personal computers, data servers and communication base stations. NSK has reduced the friction loss of the bearing for long-term reliability in harsh conditions such as operating at high speeds and high temperatures.

NSK is targeting 1 billion yen a year in global sales in fiscal 2017.

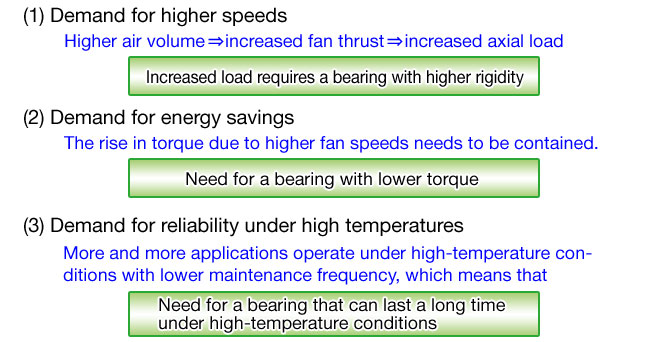

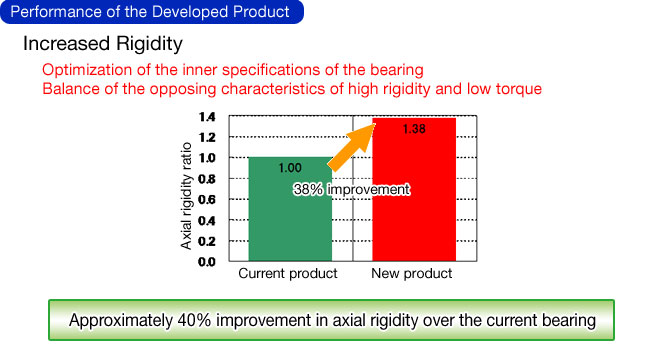

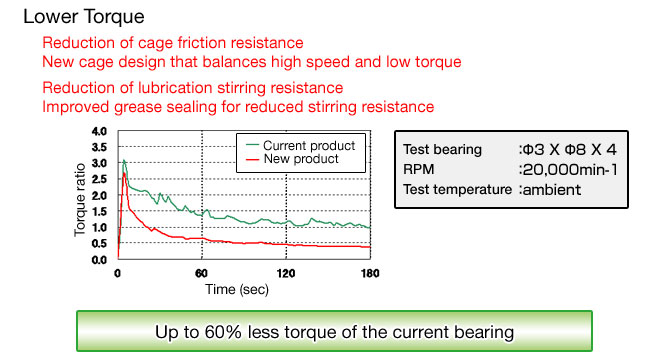

Cooling fan motors are widely used in a variety of applications such as personal computers, home appliances, office automation equipment, audio-video equipment, power supply units and data servers. In particular, cooling fan motors for data servers are used continuously for long periods of time in harsh conditions such as operating at high speeds and high temperatures. This situation is driving the demand for a bearing that can last a long time under high temperatures and keep friction at a minimum during high-speed operation. In response to this demand, NSK has developed a cooling fan motor bearing that covers a wide range of applications and operating conditions, including general-purpose operations and the more severe operating conditions just mentioned, while also contributing to energy savings.