Tokyo, Japan, December 10, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a compact, lightweight planetary needle bearing for planetary mechanisms*1 used in automobile automatic transmissions (AT), continuously variable transmissions (CVT), hybrid systems (HEV) and wheel hub motors*2.

This product employs a nylon resin that is reinforced with glass fiber for the bearing cage, thereby making the bearing more compact and lighter for a greater level of fuel economy while still maintaining a high level of reliability. NSK is targeting 500 million yen a year in sales by 2017 for this product.

In recent years the fuel economy of automobiles has been advancing worldwide. As a result, there has been an urgent demand for the transmissions used in automobiles to be more compact, lighter and more efficient than ever. In order to make transmissions more efficient, there has been a trend to use less oil and to use oil with lower viscosity. As a result, planetary mechanisms used in transmissions are being exposed to severe conditions where there is a very small amount of lubrication.

In response to the needs of more compact and lighter transmissions with less lubrication, NSK has developed a planetary needle bearing that employs a resin cage.

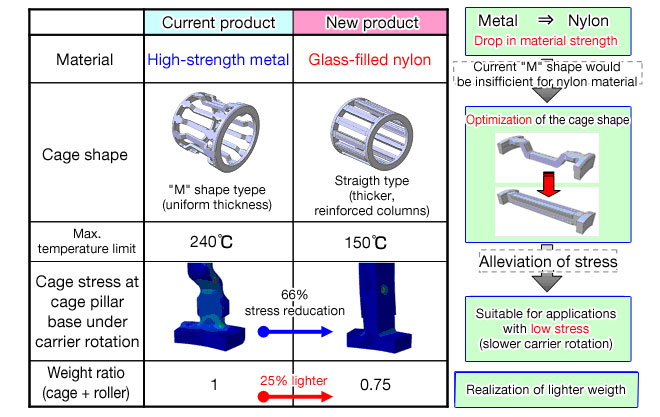

In applying resin as the material for the bearing cage and optimizing the shape of the cage, NSK has been able to realize the following superior features.

- (1) Lighter

- 25% lighter bearing weight is achieved by changing from a metal cage to a resin cage

- (2) Compact

- 10% slimmer bearing width through optimization of the number and length of rollers while maintaining the same level of bearing capacity

- (3) Compatible with reduced oil quantities and lower viscosity oils

- An oil pooling feature in the cage makes it possible to use transmissions that use less oil and/or oils with lower viscosity

- (4) Can control lubrication volume

- A discharge groove in the cage makes it possible to control the amount of oil that passes through the bearing

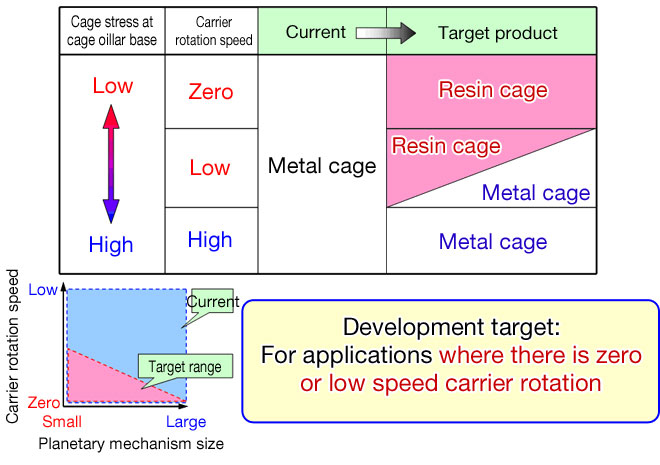

This product is ideal for needle bearings used in applications with low carrier rotation speeds.

This product facilitates the design of compact and efficient transmissions for automobiles.