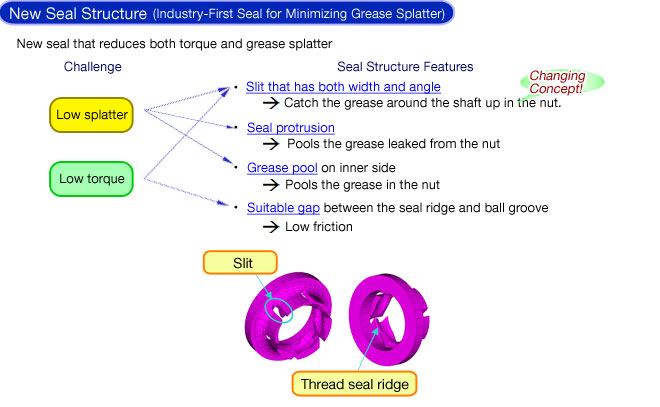

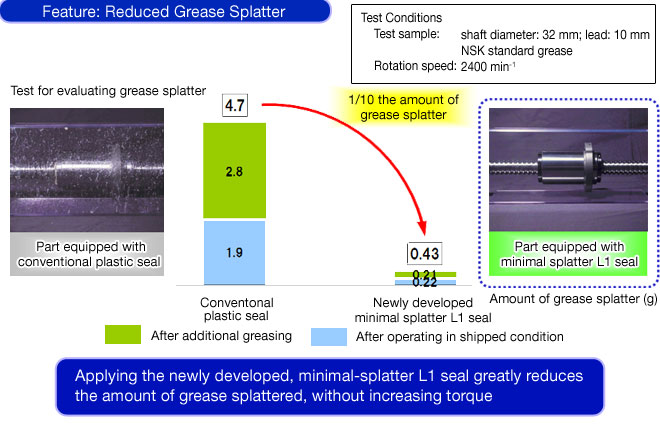

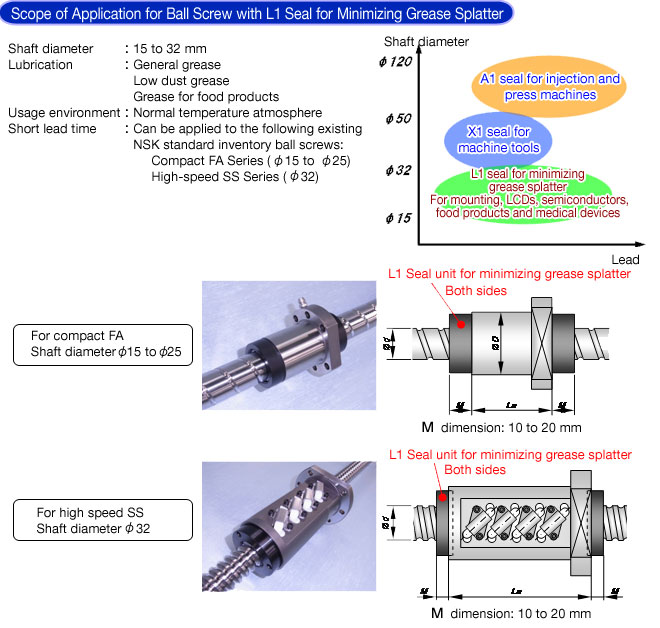

Tokyo, Japan, October 11, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a ball screw that minimizes grease splatter thanks to the new L1 seal, an original seal NSK is positioning as an industry-first which greatly reduces the amount of grease splattered by ball screws. NSK will launch this product in January 2014 and is targeting 500 million yen in sales in 2016.

NSK will be exhibiting this product from Wednesday, October 2, 2013 to Friday, October 4, 2013 at the 16th Mechanical Components & Materials Technology Expo Osaka being held at INTEX OSAKA.