The hub unit bearing is a critical mainstay component located in the center of the wheel, supporting the vehicle frame, so it must be extremely reliable. The hub unit bearing is exposed to harsh environmental conditions such as mud, sand and water, as the vehicles are used on unpaved roads, flooded roads often seen in emerging markets, and snow-covered roads in colder climates.

In addition, as demand to reduce CO2 emissions has increased and as gasoline prices have risen in recent years, it has become imperative to improve the fuel economy of automobiles. One of the ways this issue is being addressed is by reducing the friction of all rotating parts, from the engine to the wheels, in an effort to reduce the overall running resistance of the rotating parts of the vehicle.

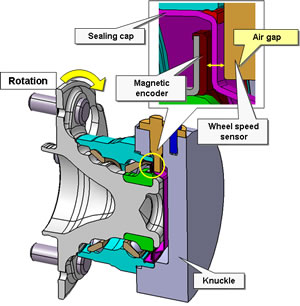

Installation of seals into both the inboard and outboard sides of the bearing is a common means of protecting the bearing interior from contamination. However, the concern with this approach is higher friction due to rub caused by the seals. As an alternative method already used in the market, a metal cap is installed on the inboard side of the bearing, but this makes it difficult to obtain sufficient sealing performance. Another difficulty of this method is the accuracy of wheel rotational speed measurement caused by the position of the metal cap between the wheel speed sensor and magnetic encoder.

Solving all of these problems, NSK has developed a nonmagnetic metallic cap with a vulcanized rubber nose gasket. Building on this technology, NSK went on to develop a high- performance sealing hub unit bearing that achieves both reliability and low-friction loss.