Tokyo, Japan, August 30, 2011 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has improved performance of its tenter clip*1 bearings - with a long life and higher reliability – for use in the tenter clips of film stretching machines.*2 NSK will promote this product in the expanding market of film stretching machines, which are increasingly in demand. The new bearings improve productivity and help save running costs. NSK expects to achieve annual global sales of 400 million yen by 2014.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

September 5, 2011

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Improves Performance of Tenter Clip Bearings for Film Stretching Machines

Contributing to improving productivity and saving running costs

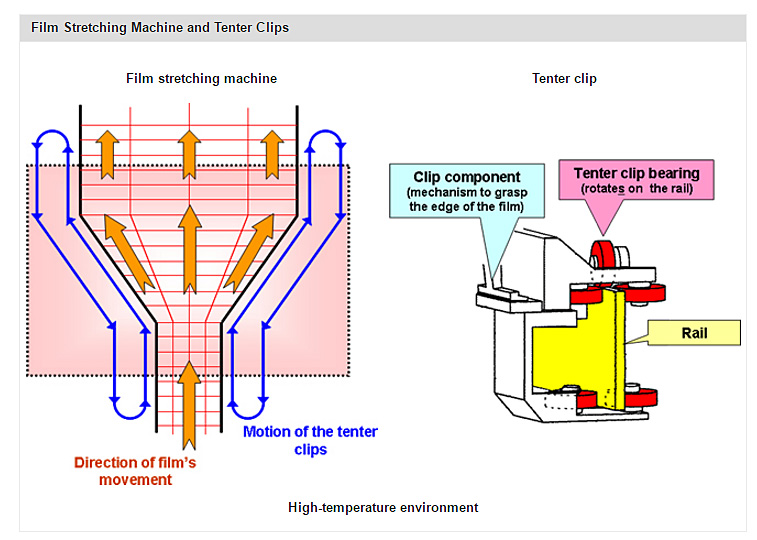

*1 A machine component that grasps both sides of a length of film and stretches the width of the film as it conveys it along caterpillar rails. Tenter clip bearings are used as guide components for the rotate on the rails.

*2 A device that stretches the width of film as it simultaneously conveys and heats it, mainly for the purpose of increasing the strength of the film (there are cases in which the length as well as the width of the film is stretched).

Background and market needs

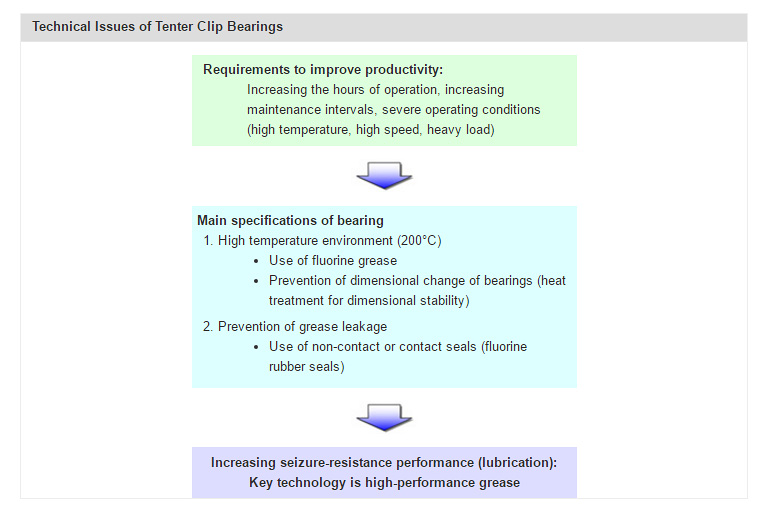

Oriented film is used as part of general-use packaging material, liquid crystal panels, and secondary batteries. Because worldwide demand is increasing, more efficiency and productivity is required of film stretching machines. Thus, bearings used in tenter clips must be completely reliable. They must have zero grease leakage, which can damage the film, and they must be able to perform under severe operating conditions, such as long operation times, fewer regular maintenance checks, high temperatures, high speeds, and heavy loads. One of the most challenging technical issues has been extending the lifespan of bearings used in high-temperature conditions.

In order to fulfill these needs, NSK has greatly improved the reliability of its tenter clip bearings, which enjoy great popularity in Japan as well as in Europe and the U.S., by packing them with a fluorine grease developed by NSK that provides excellent lubrication even in high-temperature conditions.

Product feature

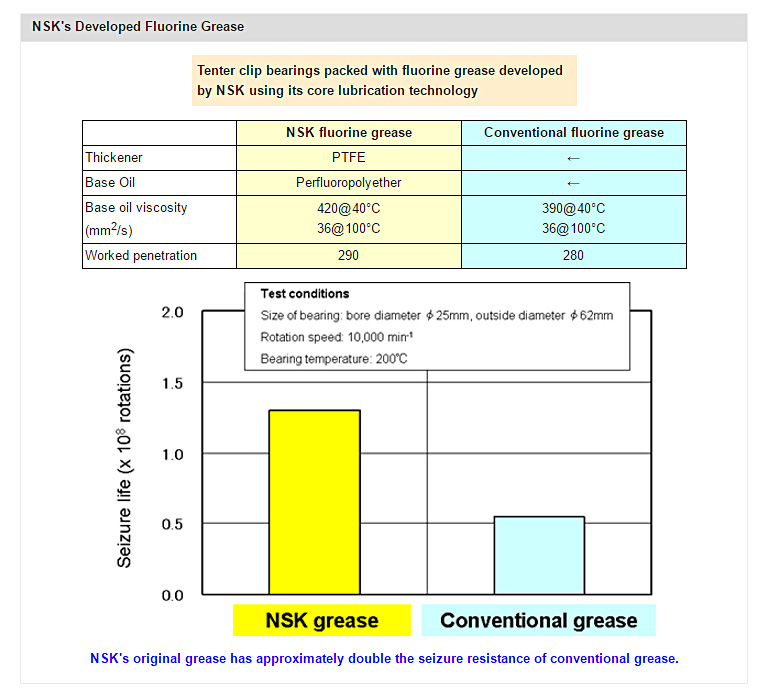

- ◆Bearing life twice as long as previous bearings

- Bearings sealed in NSK's developed fluorine grease last up to twice as long in high-temperature conditions as bearings sealed in conventional fluorine grease.

Product benefit

Longer bearing life means machinery can be in operation for longer periods of time and fewer maintenance checks are necessary. This leads to higher productivity and lower running costs.

The future

NSK will include more sizes and specifications in its lineup of tenter clip bearings in order to increase global sales not only in Japan, the U.S., and Europe but also in emerging countries such as China.