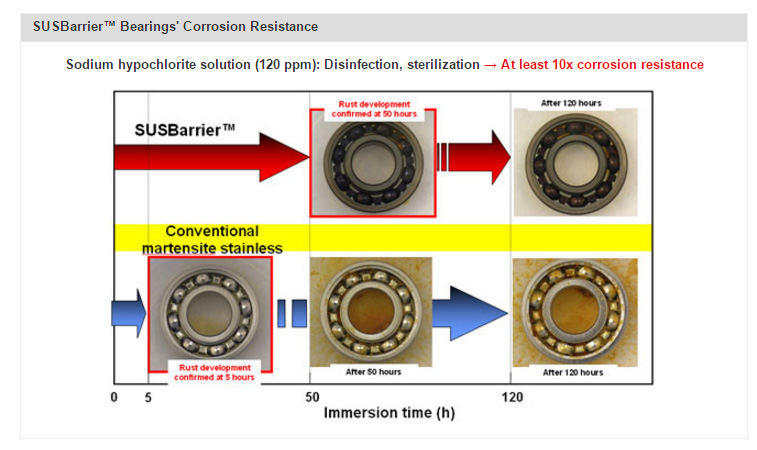

Tokyo, Japan, June 22, 2011 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed SUSBarrier™ bearings featuring corrosion resistance at least 10 times* higher than conventional martensite stainless steel bearings. NSK will market this product for food machinery, medical industry production equipment, and other devices that are exposed to splashes of disinfectants, sterilization agents, salt water, or water, and for use in other corrosive environments. It expects sales of 300 million yen in fiscal 2014.

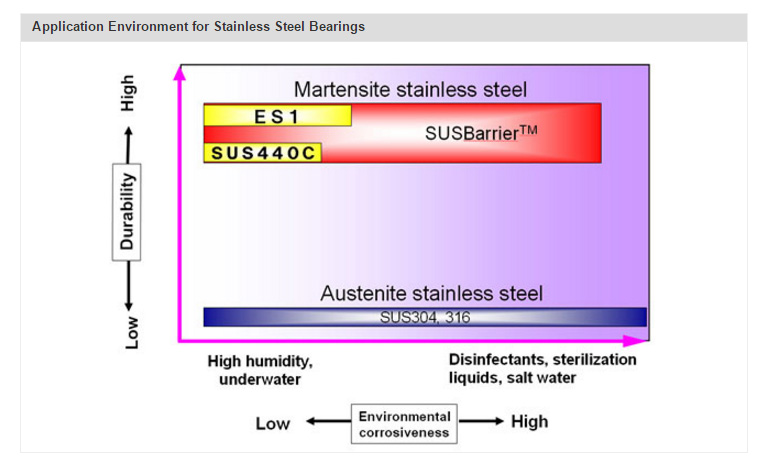

Martensite stainless steel bearings (hereinafter stainless steel bearings), which are more corrosion-resistant than regular steel bearings, are widely used in severe environments such as high humidity and underwater.

NSK's highly corrosion-resistant ES1 stainless steel, which is suited to wet environments such as underwater or where water is sprayed, and improves the corrosion resistance of regular stainless steel bearings, has been well received in the market. In addition to these wet environments, NSK has developed technology to further extend service life under more severely corrosive environments where rust and corrosion occur easily, such as in environments involving disinfectants, sterilization agents, and salt water.

NSK has now developed SUS Barrier™ bearings, stainless steel bearings with improved corrosion resistance achieved by forming a strong oxide layer on the surface of martensite stainless steel. This will help extend equipment maintenance intervals and improve production efficiency in water spray and other wet environments as well as for food processing equipment and medical industry production equipment, which are disinfected and sterilized frequently in a constant cycle, and for equipment such as conveyors in the fisheries industry, which are exposed to salt damage.

NSK will exhibit this product at the 24th Interphex Japan pharmaceutical event, which will be held at the Tokyo Big Sight from Wednesday, June 29 to Friday, July 1.

- ◆Contribution to the environment

- The product's improved corrosion resistance extends the bearing replacement cycle, improves production yield, and reduces material use and energy use at the production stage.

Going forward, NSK will continue enhancing its SPACEA™ Series by developing highly functional products suited to corrosive, vacuum, high temperature, and other special environments in order to meet diverse industrial needs.