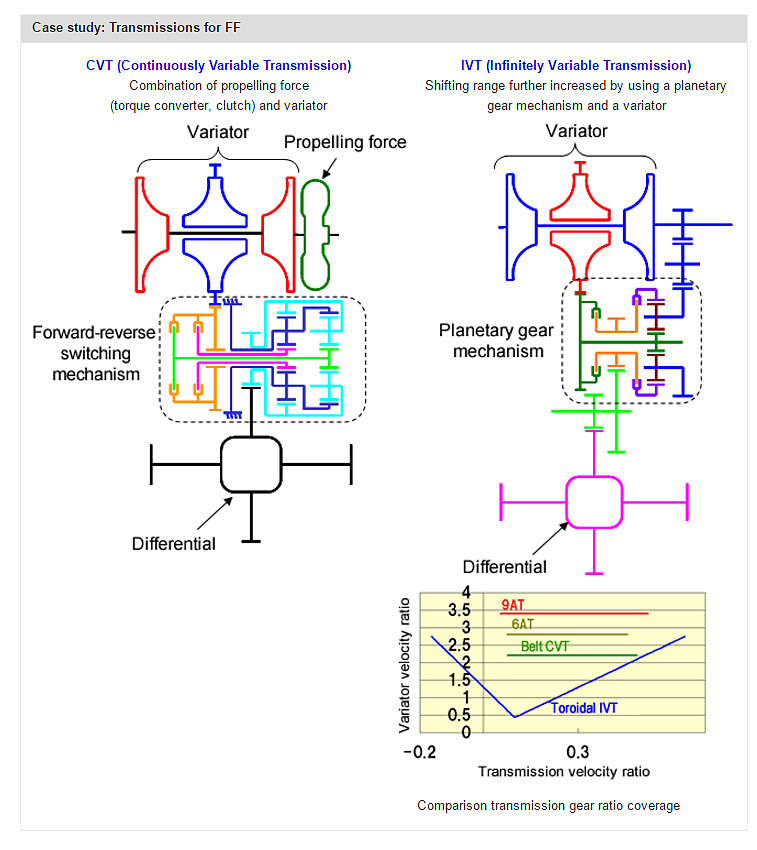

Tokyo, Japan, November 28, 2011 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed the world's first*1 toroidal variator*2 for use in front-engine, front-wheel drive (FWD) vehicles. The new product surpasses both the multi-step automatic transmission (AT) and the belt-drive continuous variable transmission (CVT) in fuel economy.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

November 29, 2011

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Develops a Highly Efficient Toroidal Variator Module for Front-wheel Drive Automobiles

More compact, lighter weight module increases efficiency and contributes to better fuel economy

NSK will exhibit this product at Tokyo Big Sight (located in Koto Ward in Tokyo) from Wednesday November 30 to Saturday December 11 at the Tokyo Motor Show 2011.

*1 as of November 2011 (NSK Ltd.)

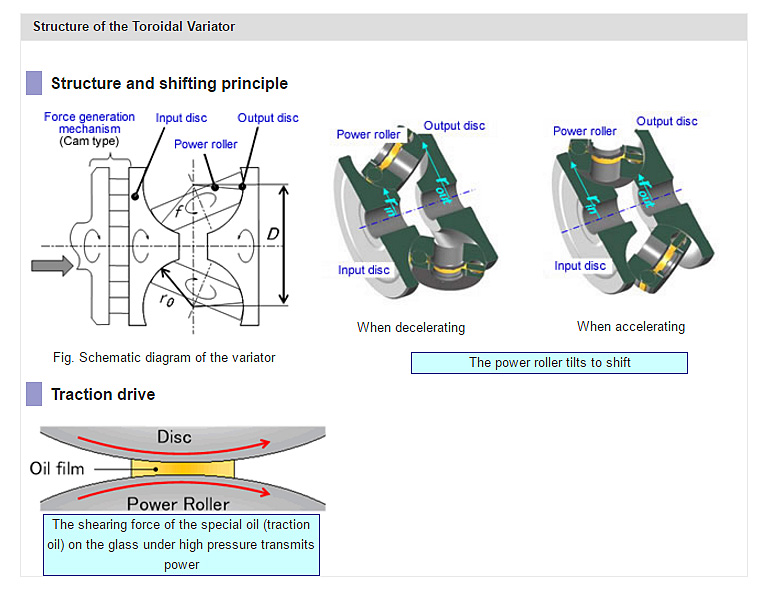

*2 Toroidal variator: A transmission that enables continuously variable shifting without a speed changing gear. It provides a smooth ride and improved fuel economy because it avoids clunky or lurching gearshifts by maintaining the transmission in the optimum gear ratio for engine speed. NSK's new toroidal variator has a wider gear ratio coverage and better efficiency than the toroidal CVT.

Product features

- ◆World's first toroidal system for FWD vehicles

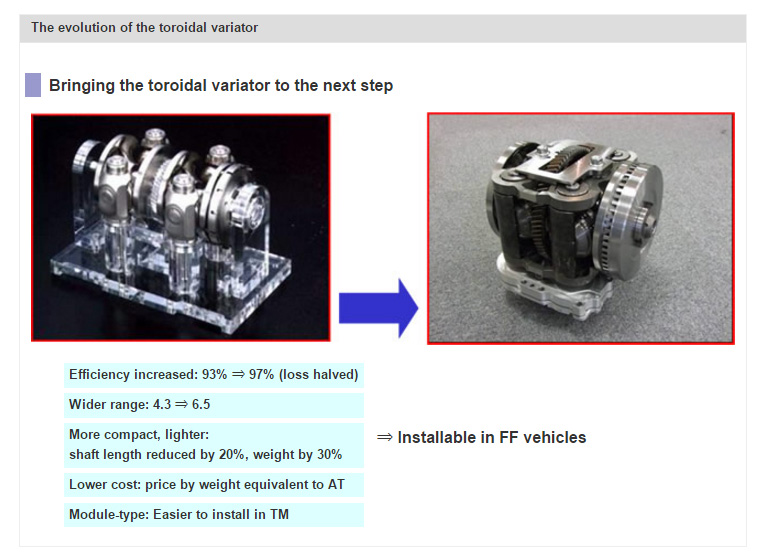

- Conventional toroidal CVTs were available only in front-engine rear-wheel drive vehicles such as large-sized vehicles, due to the space required. NSK's new system changes internal specifications and uses more compact components. These improvements have resulted in a device 20% shorter than the conventional product, allowing for installation in FWD vehicles. Weighing 30% less than the conventional product, the toroidal variator can be utilized in a wide variety of vehicles.

- ◆Improved transmission efficiency

- Transmission efficiency that is superior to even the highest efficiency conventional products. Friction has been reduced by 50%.

- ◆Wider range

- Increasing the gear ratio has made lower engine speed at a wider range of speeds possible.

- ◆Module design

- Conventional toroidal CVTs have to be at least partially assembled after their delivery to the auto manufacturer. NSK's new toroidal variator is constructed as a module that is ready as-is for installation. This leads to improved productivity for auto manufacturers.

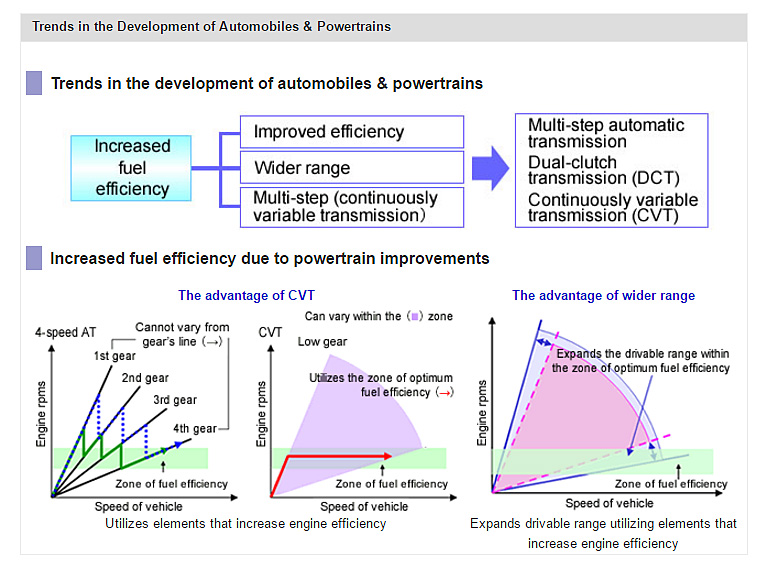

Development background

In response to higher fuel prices and tighter regulations on fuel economy, transmissions have had to become more and more efficient, leading to the development of multi-step AT systems and transmissions with smaller size and lower weight and friction loss. In 1978, NSK began developing a half-toroidal CVT system. The company developed its own unique, highly-clean carburizing steel for use in CVT systems utilizing its bearing technology. Using carbonitriding heat treatment technology and ultra-precision surface processing technology, NSK developed the world's first power rollers and discs for automobiles that satisfy durability standards. In the process of developing its toroidal CVT system, NSK applied for over 1,000 patents around the world.

In 1999, NSK successfully developed the world's first half-toroidal CVT (a traction-drive continuously variable transmission) and then succeeded in applying this technology to aircraft. Improving on its toroidal CVT, NSK's new toroidal variator for vehicles can be installed in a wide variety of vehicles and delivers significantly improved fuel economy.

NSK has achieved compact, lightweight and low torque applications for automobiles by leveraging its four core technologies (tribology, materials, analysis, and mechatronics). The company has been developing these technologies for over 90 years and is continuing to create innovative new products that will improve the fuel efficiency of automobiles.