Tokyo, Japan, October 25, 2010 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced plans to market a new lineup of small-bore (inner diameter 6 to 25 mm), angular contact ball bearings with seals designed for use on the main spindles of machine tools in November 2010. NSK continues to play its part in improving both the productivity and environmental performance of machine tools. The company is targeting annual sales of 400 million yen by 2011.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

November 17, 2010

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK to Release Small-Bore, High-Precision Angular Contact Ball Bearings with Seals for Machine Tool Applications

Use of Grease-based Lubricant Contributes to Higher Machine Tool Productivity and More Environmentally Friendly Design

Development background

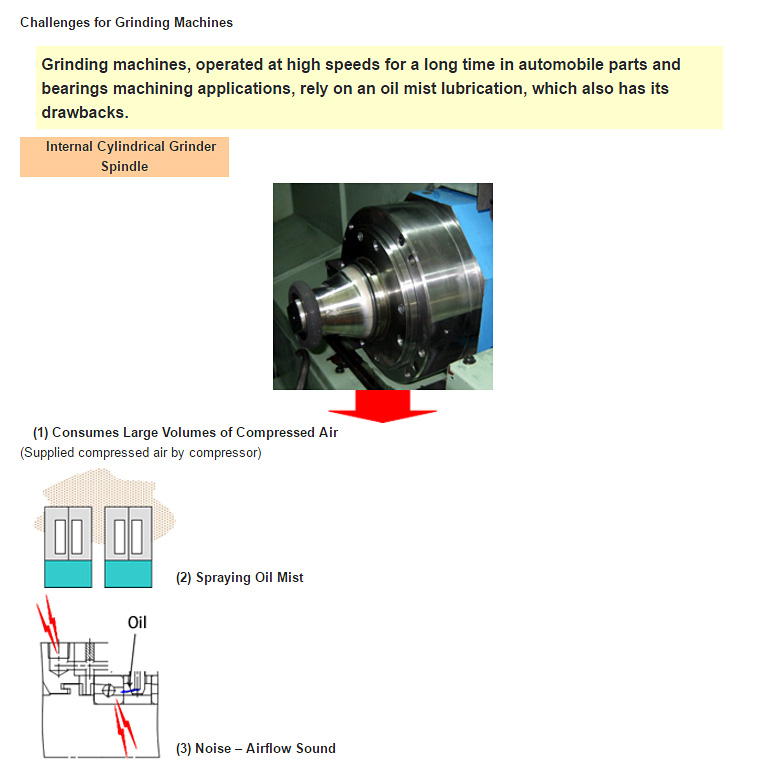

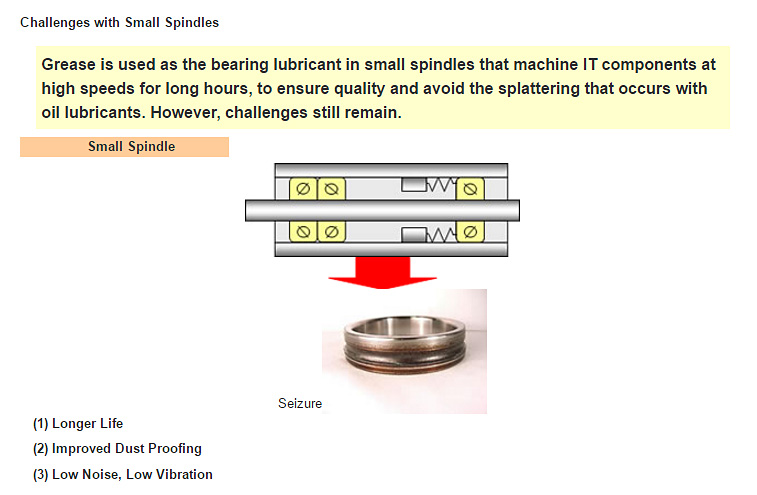

The grinding machines used for machining small automotive parts and components and bearings are designed to operate at high speeds for a long time. Oil mist type lubricant*1 is used to ensure good service-life for bearings that operate under such demanding conditions. While the small spindles used for machining very small IT components operate under the same, extremely demanding high speeds and long operation times, grease has been adopted to avoid the problem of splatter caused by oil lubricants, thereby improving the quality of the machined products.

NSK has adopted noncontact seals and a low vibration cage, along with its own special grease, as the principal design features for the small-bore (inner diameter 6 to 25 mm) ball bearings widely used in applications of this type. NSK's new grease-lubricated, small-bore, angular contact ball bearings have now made the breakthrough to high rotation speeds formerly only attainable using oil-based lubricants, thereby significantly extending product life. The grease-based lubricant also contributes to both energy conservation and the environment. And the improved environmental performance does not inhibit productivity in the least.

*1 Oil-mist lubrication: This method involves the use of streams of compressed air to spray lubricant onto the bearings. While this provides high quality lubrication, it also consumes large volumes of compressed air generated by an electrically powered compressor. The high CO2 emissions generated have become a major environmental issue.

Product features

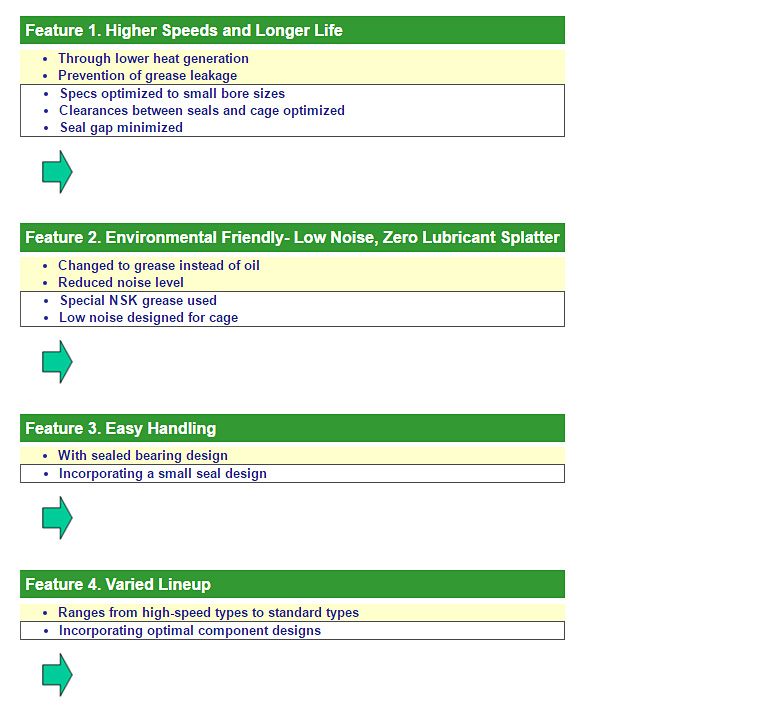

- Higher speed(s) and longer service life

-

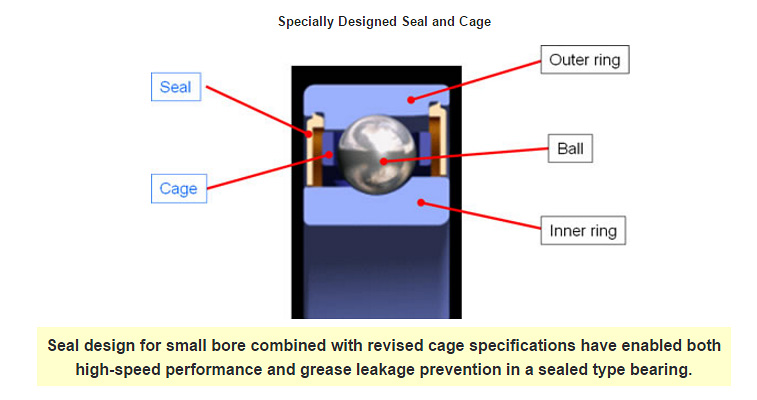

- Incorporating specially designed noncontact seals and a low vibration cage, the small-bore, angular contact ball bearings make it possible to combine highly dustproof characteristics with the kind of high-speed performance that was heretofore only attainable with oil-based lubricants.

- Filling the new small-bore, sealed type angular contact ball bearings with NSK's own special grease, widely market recognized for its performance, has helped extend the life of the bearings by 1.5 times over the unsealed type.

- Environmentally friendly

-

- These ball bearings no longer spray lubricating oil into the atmosphere.

- Easy handling

-

- The ball bearings come with lubricant sealed inside, making them much easier to handle and work with.

- Wide variety of lineup

-

- The new ball bearing comes in standard and high-speed types, with inner diameter ranging from 6 to 100 mm, making them adaptable to a wide range of applications.

Applications of Small-Bore High Precision Angular Contact Ball Bearings

Applications of Small-Bore High Precision Angular Contact Ball Bearings

Features of Small-Bore, High Precision Angular Contact Ball Bearings with Seals

Specs for Small-Bore, High-Precision Angular Contact Ball Bearings with Seals