Tokyo, Japan, March 24, 2010 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) announced today that it plans a major, threefold expansion in its lineup of NSK Linear Guides with the addition of precision-grades and medium preload random matching products. The new products will be available starting in April 2010.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

April 13, 2010

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Plans Major Expansion of NSK Linear Guides Lineup With New Precision-Grades and Medium Preload Random Matching Products

Meeting Diverse Market Needs for Shorter Delivery Times With the Addition of High-Precision, High-Rigidity Products

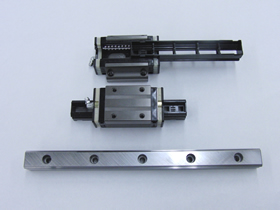

Products in the main series of NSK Linear Guides—the LH, SH, LS, and SS series—are widely used for general industrial purposes, including all manner of applications in semiconductor and liquid crystal manufacturing equipment, automobile manufacturing equipment, general machinery, transport robots, and machine tools. NSK now plans to add precision-grades and medium preload random matching products to its lineup. Featuring better running parallelism and rigidity achieved by improving the precision of rails and ball slides, these products were developed to meet the demand for shorter delivery times of high-precision, high-rigidity products in commercially available formats, for small to medium-sized manufacturers, and for China and other countries/regions in the Asian market. The addition of these new products represents a major expansion, tripling the size of the lineup.

NSK will launch sales of these products in April 2010, aiming for annual sales of 2 billion yen by 2012. It will also exhibit the products at the Techno-Frontier 2010 trade fair in July 2010.

Product features

- Improved fabrication accuracy enables interchangeable precision and preload products

- Improved accuracy in the processing of the raceway and installation surfaces for the rails and ball slides has resulted in motion accuracy improved by half of normal grade. Strict dimension tolerance control in rails and ball slides has achieved an ideal preload, resulting in twice the rigidity compared to conventional slight preload products.

- Gives freedom to mix and match precisions and preloads and greatly expands flexibility for combining rails and ball slides

- The addition of precision-grades and medium preload random matching products greatly expands NSK's lineup by enabling 122 combinations in contrast to the 44 possible combinations with conventional products. This greater number of possible combinations will meet the diverse needs of customers.

- Shorter delivery times now possible for high-precision, high-rigidity products

- The addition of precision-grades and medium preload random matching products, together with NSK's original workshop system for combining ball slides with rails cut to customer specifications, enables shorter delivery times worldwide for high-precision, high-rigidity products.

Applications: Liquid crystal and semiconductor manufacturing equipment, automobile manufacturing equipment, general machinery, transport robots, machine tools, etc.