Tokyo, Japan, October 18, 2010 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced it has developed a new product application for its HMS Series ball screws designed for use in high-speed machine tools. NSK plans to start sales of the new HMS Series ball screws in April 2011 and is targeting annual sales of 1 billion yen by 2013.

Global

ASEAN and Oceania

Middle East

Africa

Press Release

October 20, 2010

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Develops New Product Application for HMS Series Ball Screws for High-Speed Machine Tools

Series Contributes to Higher Speed, Lower Noise and Lower Vibration Operation

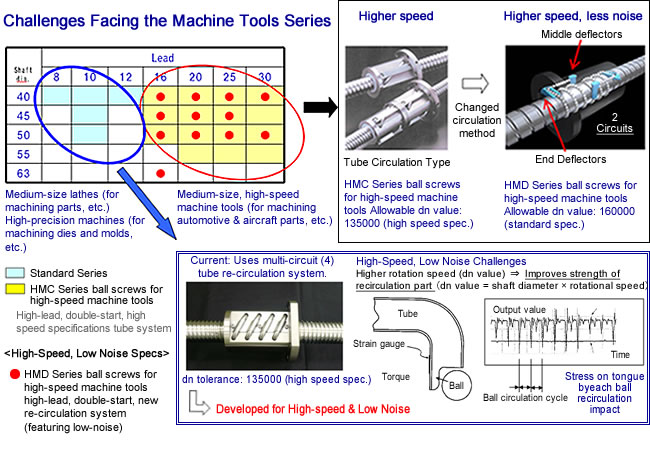

Machine tools used for high volume machining of large parts and components used in automobiles and aircraft. Such high-precision applications as die machining, on the other hand, require ball screws with small leads. In such applications, demand has grown recently for ball screws that meet the dual criteria of higher speed, which improves productivity, and lower noise and vibration. The new HMS Series ball screws have been developed specifically for the high-speed machine tools used in such applications.

NSK exhibited the HMS Series ball screws at the “25th Japan International Machine Tool Fair (JIMTOF2010)” held recently from October 28 to November 2 at Tokyo Big Sight (Koto Ward in Tokyo).

Product features

- High-speed performance

-

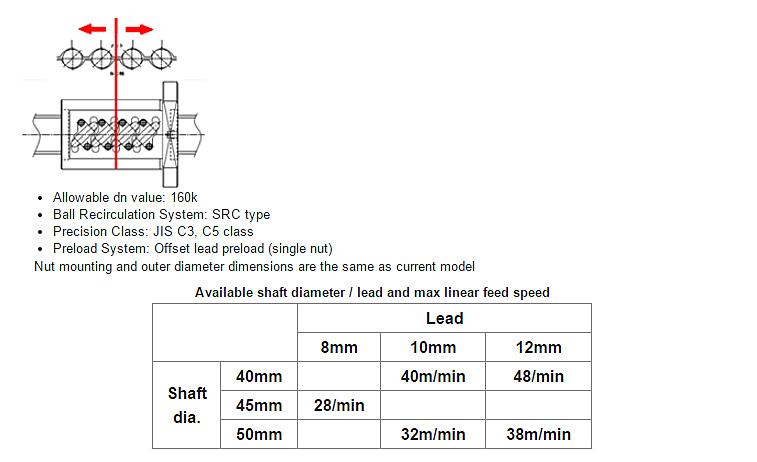

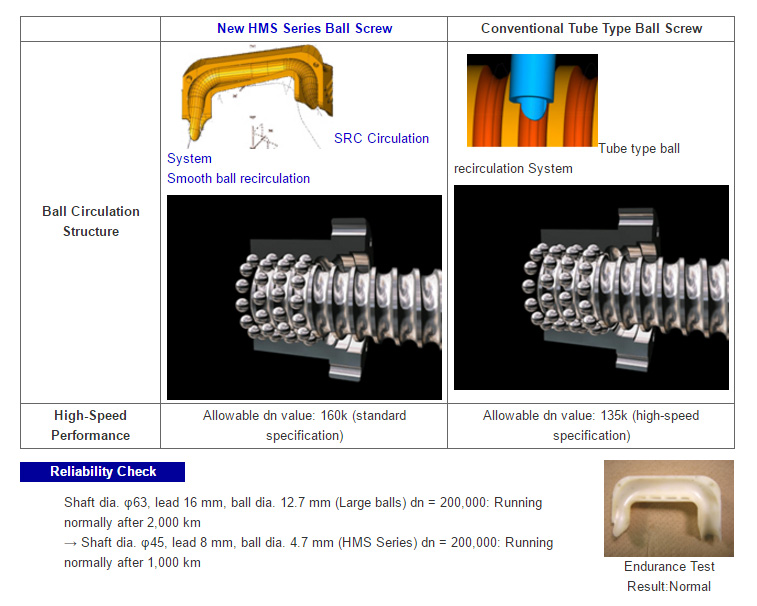

The HMS Series ball screws are based on the SRC circulatory system that incorporates NSK's proprietary high-speed and low noise and vibration technology to ensure smooth ball circulation. As a result, an allowable dn value*1 approximately 20% higher (i.e., 160000) than that of the existing tube circulation system has been achieved. Linear speed has also reached 48 m/min (with 40 mm shaft diameter and 12 mm lead). These ball screw specifications will contribute to higher productivity in machine tool applications.

*1 The dn value is defined as “Shaft diameter d (mm) × Rotational speed n (min-1)”

- Low-noise, low vibration performance

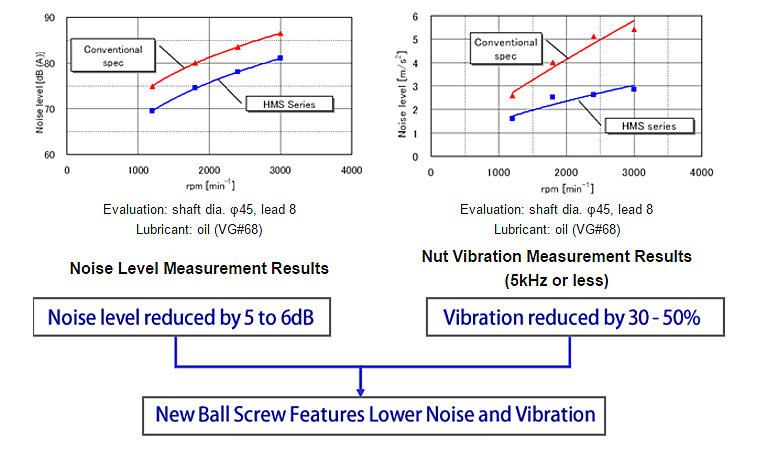

- Adopting the SRC configuration for the circulation system has enabled reductions of 6dB (A) in maximum noise level and 50% in vibration. These two factors help to ensure a more worker-friendly production environment and higher precision machine tool performance.

- Environmental considerations

- The new HMS Series ball screws contain no materials considered harmful to the environment.

- Development background

- NSK first developed high-speed, low-noise ball screws in 2003, which were marketed as the BSS Series. This was followed by other market-leading series of high-speed, low-noise ball screws geared to a broad range of industry applications. The HMS Series, newly developed for the high-precision die machining tools sector, is nearly ready for market. NSK will continue to provide solutions based on its high-speed, low noise technologies for various industry markets.

Development Background

Features: High-Speed Performance

Features: Low-Noise, Low-Vibration Performance

HMS Series Specifications