Global

ASEAN and Oceania

Middle East

Africa

Press Release

July 3, 2008

NSK Ltd.

CSR Division Headquarters

Public Relations Department

NSK Develops Manipulation System that Enables Fine Processing

Tokyo, Japan, July 2, 2008 - NSK Ltd. today announced it has developed a micro-manipulation system that facilitates the handling of microscopic items. With the ability to manipulate items as small as a single cell, the new system can be used in a variety of medical science and biotechnology applications. Nanotechnologists will also find the system useful in assembling microscopic tools.

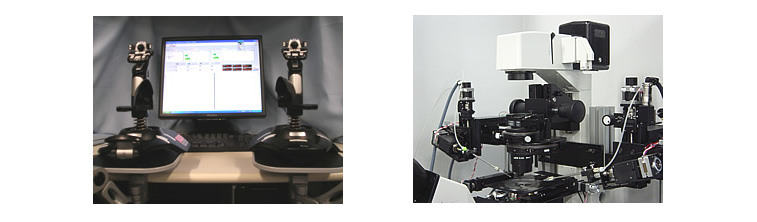

With a proprietary piezoelectric actuator that makes it easy to operate, the system features a three-axis (XYZ) positioning stage that facilitates the attachment of measuring devices, micromanipulators and microscopes for examining a preparation.

In developing the system NSK was supported by extensive in-house expertise in integrated mechatronics and precision positioning drive technology - knowledge accumulated over decades of experience in developing related technologies such as bearings, mechatronics products and image-processing technologies. One key advantage for the development team was NSK's ultrafine positioning technology. Used in the system's nanopositioner, and driven by a rotary motor, this technology uses a piezoelectric element for fine motion positioning control of various setups and micromanipulators.

The system's ability to manipulate cells is currently being evaluated by Professor Naomi Kashiwazaki of the School of Veterinary Medicine at Azabu University.

Combined with the latest in image processing technology, the new NSK micro-manipulation system meets market demand for a system that is both highly accurate and easy to operate. Aiming at commercialization within the next year, NSK will exhibit the system this month at the 7th Bio Expo Japan and present papers at the Bio Research Support Products and Technology Seminar.

Features

- 1. Highly accurate positioning of stage and stage attachments

- Highly accurate positioning is enabled by NSK's Nanopositioner, which includes proprietary technology in its rotary motor and ball screw. In combination with NSK's high-resolution piezoelectric drive mechanism, these components facilitate ease of operation, highly accurate positioning and coarse motion drive of various stage attachments.

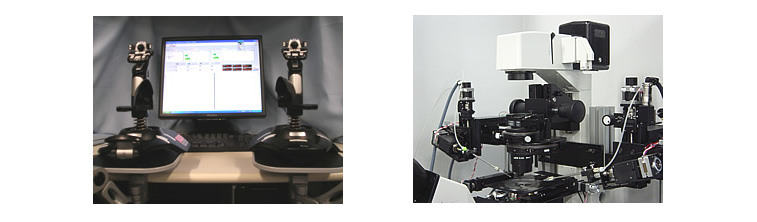

- 2. Ease of operation

- Thanks to a high degree of automation even a relatively unskilled operator can position a specimen and perform functions that would have previously required a highly skilled operator.

- 3. Enhanced safety

- The system enhances safety by enabling operators to perform intracytoplasmic sperm injection (ICSI) without using mercury. Small amounts of mercury are typically used to stabilize the pipette tip when piezoelectric force pulses are applied during ICSI. Removing the need for mercury eliminates handling and waste disposal concerns.

Manipulation systems for ultrafine positioning are used in various fields covering medical practice, biotechnology, semiconductor manufacturing, and electronics, and conventionally required highly skilled operators. Combined with information technologies and metrology engineering, manipulation systems can be applied to a wider range of uses in science and technology, and can be used by a larger number of operators with minimal training.

With its high-precision positioning drive technology NSK's manipulation system offers a new standard of accuracy and efficiency. This is one example of NSK's ongoing commitment to innovation in our four core technologies: tribology, materials, analysis and mechatronics.