Steel & Metals

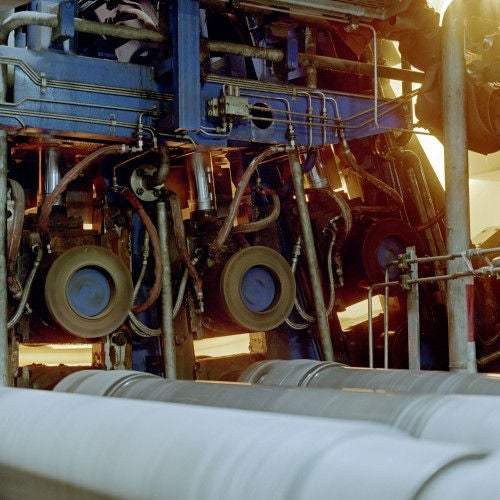

In the steel industry, bearings can be found in a vast range of plant and equipment that is used in both upstream and downstream processes: from the storage yard for raw materials to the steelmaking, rolling and refining processes. All kinds of bearings are used in this plant and equipment.

The operational environment for these bearings is unique to steelmaking, comprising steel dust, water, and heat. In addition, the bearings may have to cope with heavy loads and vibration shock, operational speeds ranging from extremely slow through to high, coupled with rapid acceleration and deceleration. This makes for a demanding operational environment that is not found in other applications.

NSK aims to make a positive contribution to improving operational stability and productivity. These are issues crucial to the steel industry, which is representative of the industry which manufactures production equipment. NSK achieves this aim by

the application of high-level bearing design technologies

ongoing planning, development, and R & D from many different perspectives, including bearing technologies of materials, lubrication, and analysis.

Over many years, this has led to the implementation of strategies for attaining the company's fundamental goal: producing bearings with a long operating life and high reliability. NSK offers a comprehensive lineup of bearings for the steel industry, from standard bearings meeting ISO standards through to its own independently developed, high-capacity specialized bearings.

NSK is now also responding to the need for high added-value products and an environmentally friendly approach in the steel industry.

A typical problem for bearings in converters: the swivel bearing cannot be replaced without dismantling the central wheel.

NSK's ultra-large split Spherical Roller Bearings allow bearing replacement without removing the central wheel of the gearbox, thus reducing maintenance cost and shortening downtimes.

Ultra-Large split bearings

Ultra-large split bearings for BOF's & Converters making maintenance & bearing changes less time consuming. >>

Differential speeds in the roller/raceway contact zone can cause uneven wear in spherical roller bearings and toroidal roller bearings. Spalling and cracks on the raceway of the outer ring are costly as they cause unplanned production stoppages and above-average consumption of bearings.

To tackle this problem, NSK has developed a range of full complement cylindrical roller bearings effective as non-locating position in guide rolls of continuous casting machines.

Cylindrical Roller Bearings - NUB Series

In order to meet the requirements of steel making equipment and continuous-casting machines, NSK has expanded its range of cylindrical roller bearings. NSK has developed the new NUB series which can reduce the total cost of ownership for continuous casting machine guide rolls >>

SWR Series Roller Bearings

This type of spherical roller bearings provide solutions to challenges in continuous casting guide rolls. >>

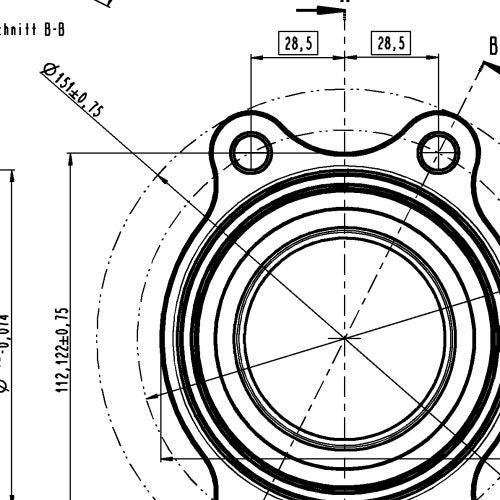

NSK offers specific bearings for rolling mills which guarantee higher reliability and longer operational service lives.

Sealed bearings minimise the environmental impact and help reduce grease consumption.

Super-Tough steel (STF series) with optimum heat treatment prevents cracks and early raceway damage.

In addition, NSK has developed WTF material (WTF series) for bearings which are exposed to water infiltration.

The four-row extra-capacity sealed-clean taper roller bearings (KVS series) are capacity-optimised, resistant to contamination by foreign matter and now also available with specially formulated grease against water infiltration.

Four-Row CRB with Stud-Type Cage

These bearing are designed to prevent cracking of rollers generated by extremely heavy rolling loads. >>

Taper Roller Bearings - 4 rows - Long Life

NSK solution for four-row tapered roller bearings in rolling mills. These bearings offer long service life, reduced maintenance cost and increased operational efficiency.

Optional we offer: Super TF, WTF, Sealed Clean and

new grease AQGRD >>

Long-life sealed backup roll bearings

Specifically designed for cluster and sendzimir mills to achieve long life and high speed operating conditions. >>

NSK Success Stories

Customer cost savings is the best reference of our success. Example Success Stories by industry are listed below >>

Technical Enquiry

Looking for a new solution? Fill out the technical enquiry form and one of the NSK technical team members will provide assistance as soon as possible. >>

Troubleshooting

Don't let your bearings fail prematurely or unexpectedly. Save yourself trouble and money with the NSK troubleshooting tools. >>