Paper

The pulp and paper industry continues to make great strides in productivity with enhanced speeds and wider wires. To avoid unexpected downtime, bearings in papermaking machines must be highly reliable.

NSK offers a complete bearing lineup for all roll sections of modern papermaking machines, with specialized solutions that keep production moving.

- Tough Long-Life TL Bearings

Designed specifically for dryers, TL bearings take full advantage of NSK's materials and heat treatment technologies. - NSKHPS™ Spherical Roller Bearings

NSKHPS bearings integrate NSK's unique materials, design knowhow, and manufacturing technologies into a high-performance standard.

Never settling, we continue to pursue ever more reliable bearings that further improve productivity with less waste.

From troubleshooting to on-site training, NSK Industry Specialists bring unparalleled knowledge and experience to the pulp and paper industry. Our experts specialize in paper process,machinery and specific mill applications to help maximize productivity and reduce cost with:

- Bearing failure analysis

- Mill assessments to reduce maintenance cost and increase efficiencies

- Technical support during mill outages for bearing dismantle and installation

- Inventory audits and Mill mapping to better manage bearing needs

- Root cause analysis

- Roll shop inspections

- Training in best practices (class room or hands on)

- Maintenance Techniques

- Maintenance Tools and Mounting

- Installation and Removal Techniques

For more information on NSK Industry Specialist contact NSK.

Operating conditions: Moisture, water ingress and high speeds

Moisture levels are high in the wire section which results in water penetration and bearing corrosion. Water ingress together with the tendency towards even-greater speeds can lead to premature bearing failure and loss of production.

NSKHPS series of bearings for very high speeds

NSK has devloped products to overcome these common issues found in paper manufacturing, NSKHPS Spherical Roller Bearings offer a 20% higher limiting speed and last up to twice as long compared to standard products. NSKHPS offer a special cage design and optimized outer ring surface, with highly accurate precision grades (P55) also available.

Operating conditions: Low / heavy loads and high speeds

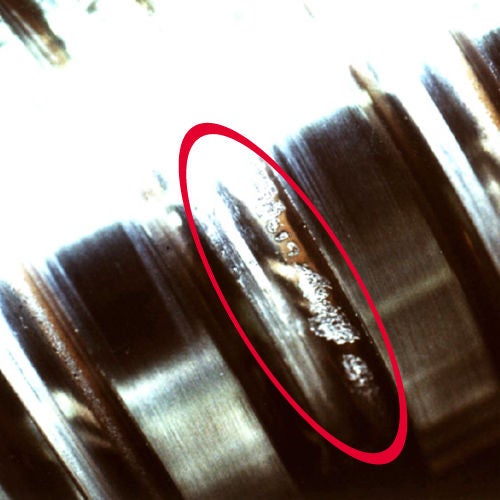

The paper industry demands highly reliable operation and long service life from their bearings. Press rolls are subject to very heavy loads, while suction press rolls reach very high speeds. Improper bearing selection for paper applications like these can quickly lead to raceway damage.

Spherical roller bearings for extremely high loads and speeds in shoe presses

In collaboration with a renowned supplier of equipment for paper machines, NSK has developed, tested and released spherical roller bearings with optimized internal design which are suitable for high, current and future, line speeds in shoe presses

Our Innovations:

Triple Ring Bearings

NSKHPS Series Spherical Roller Bearings

Operating conditions: Very high temperatures, high speeds, heavy loads

Temperatures up to 150°C are common in the dry end of paper machine. They're subject to high axial forces and tension. Due to these demanding environments, the bearings inner ring can crack, causing machine downtime and loss of production.

TL series spherical roller bearings for high temperatures

NSK’s TL (Tough & Long life) series was developed specifically for dryer rollsrunning at very high temperatures. Combined with special heat treatment, the chemical composition of the steel used makes the inner and outer rings extremely resistant to wear and cracking,dramatically reducing downtime and maintenance costs.

Our Innovations:

TL Series Spherical Roller Bearings

Cylindrical Roller Bearings with Aligning Rings

NSKHPS Series Spherical Roller Bearings

Operating conditions: High temperatures, extremely high speeds, heavy loads

Calender rolls are subject to heavy loads and high speeds which can rapidly cause fatigue in spherical roller bearings. High heat of the application causes expansion of the bearing inner ring leading to cracks, ultimately resulting in bearing failure.

Our Innovations:

TL Series Spherical Roller Bearings

Cylindrical Roller Bearings with Aligning Rings

NSKHPS Series Spherical Roller Bearings

Triple Ring Bearings

TL Series Roller Bearings

Specifically designed for dryer rolls in papermaking machinery operating under extremely high temperature conditions. >>

NSKHPS Series Roller Bearings

NSKHPS series or high performance standard uses state of the art material technology bearings, offering high speed & load ratings. >>

Molded-Oil Bearings

Molded-Oil Bearings are lubricated with NSK’s original oil-impregnated material, Molded-Oil, and are suitable for corrosive and dust-contaminated environments. >>

Deep Groove Ball Bearings

The most common form of rolling bearings, deep groove bearings are used in a variety of applications; particularly those where high speeds and low power loss are required >>

Sealed Spherical Roller Bearings

Promoting a clean working enviroment, these bearings offer long-life performance & reliability under harsh & contaminated conditions. >>

EM Series Cylindrical Roller Bearings

Features high load ratings and quiet running with precision machined tough one-piece cage. >>

Triple Ring Bearings

Triple ring bearings, two different types of inner/outer bearing combinations. Especially for papermaking machinery. >>

Share