Motorcycles

The unmatched convenience of motorcycles makes them popular worldwide, but the bearings inside are what keep rides smooth and safe.

As bikes come in all shapes in sizes, the number of bearings inside vary, but a typical motorcycle contains 20–30 built-in bearings. Motorcycle bearings reduce friction in key rotating parts, including the engine, transmission, and wheels, and the engine depends on bearings to reliably transmit power to the wheels.

Motorcycle bearings must facilitate a comfortable ride with low friction, little vibration, and high durability. All these factors also influence fuel consumption and safety—top priorities for riders. NSK product development works to optimize designs always with users and the environment in mind.

Bearings also play a huge role in a motorcycle’s sensory experience. The hum of the engine, the velvety feel of the ride, the power under your fingers– bearings influence all these factors.

NSK bearings incorporate riders’ eternal desires for an exhilarating, yet comfortable and easy-to-handle ride while ensuring reliability and safety. We continue to pursue smooth and reliable bearing rotation with reduced power losses as we move to the future.

Deep Groove Ball Bearings for Wheels

Open and sealed bearings filled with grease offer high durability.

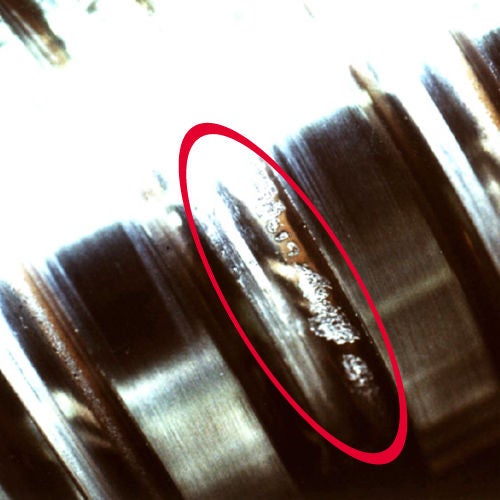

Deep Groove Ball Bearings for Crankshafts

Bearings with an anti-creep pin on the outer ring and a strengthened cage to resist vibrations and shocks.

Needle Roller Bearings for Swing Arms

A high-strength outer ring achieves high durability under heavy loads.

Ball Screws for Hydrostatic CVTs

High-efficiency ball screws help reduce motor size.

Share