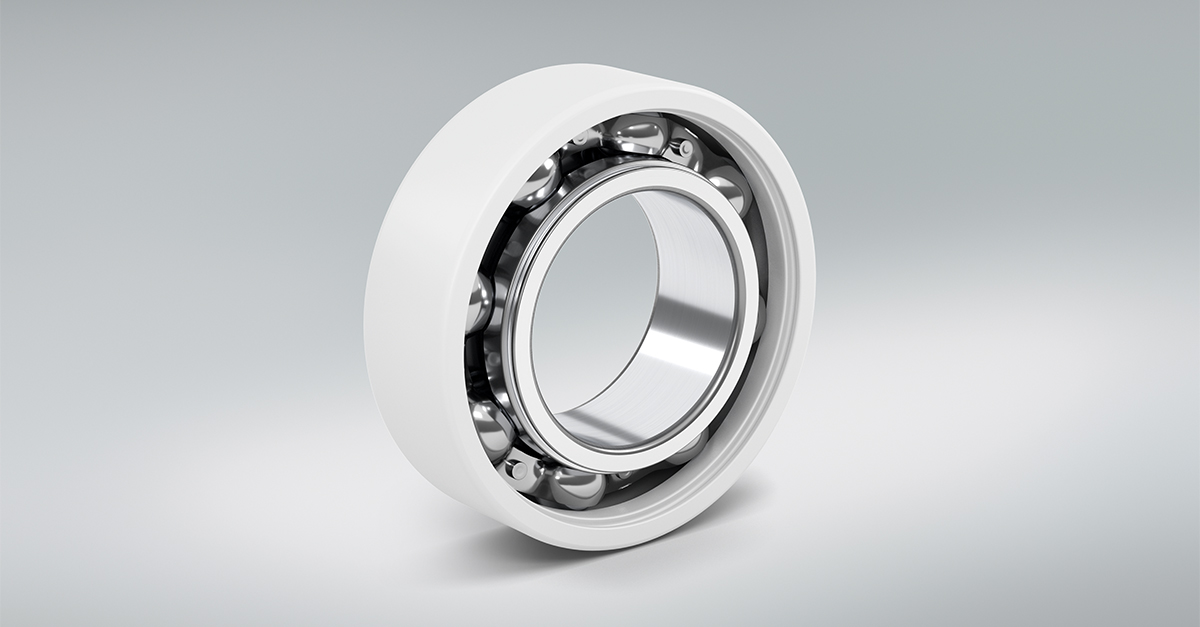

HDY2 bearings Electrical currents flowing through a bearing can cause catastrophic damage and drastically reduce its lifespan. It’s a very common problem, particularly in applications like electric motors, and one you may well have encountered in your own business. Consequences include increased downtime, production interruptions and skyrocketing maintenance and repair costs. The problem is exacerbated by the increasing popularity of inverter-controlled electric motors, due to their energy saving benefits. Unfortunately, they send currents flowing directly through the bearings… But what if the bearing itself was insulated, preventing any current from flowing through it? Then all your problems would be solved in one go! Our solution is NSK HDY2 bearings. Check out the attached PDF to learn everything you need to know about the product dimensions, details and features. If you’re interested, rest assured that we have plenty of stock available. Even though these products are manufactured at the #NSK headquarters in Japan, we keep a large supply of them at our European Distribution Centre in Tilburg, the Netherlands. If you want them, we have them.

Visit us on our social media

192 results

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

Facebook: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

Facebook: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe

LinkedIn: NSK Europe