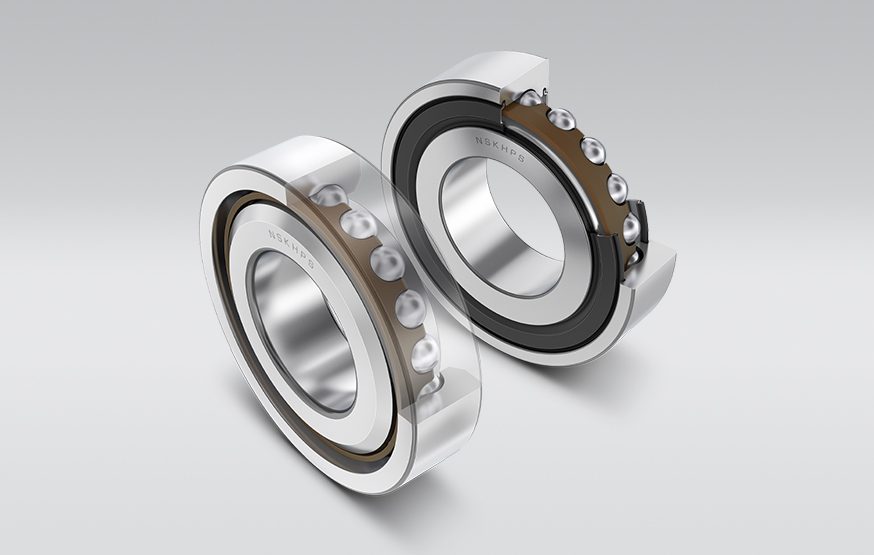

Design Features

- Manufactured with high steel purity

- Polyamide and phenolic resin cage design options meet wide-ranging application requirements

- Available with ceramic ball option for higher seizure resistance and lower heat generation

- Non-contact sealed types available

- Available with 15°, 25° and 30° contact angles

- With P2, P3, P4 and P4Y accuracy

- For dimension series 19, 10, 02

- Available for bore diameters from 10 to 260 mm

- For universal matching / arrangements

Operating Benefits

- Improved steel purity increases bearing fatigue life by as much as 15%

- High maximum rigidity for high loads and high speeds

- Sealed designs prevent contamination and lubricant degradation, with grease life extended by as much as 50%

Fields of Application including

- Machine Tools

Share