Design Features

- Bearings lubricated with oil-impregnated material consisting of lubricating oil and polyolefin resin

- Oil slowly seeping from this material provides ample lubrication to the bearing for extended periods

- Solid lubricant acts as a barrier to water and dust ingress

- Low torque is achieved for smooth rotation of rolling elements

- Compositions available for both general applications and high-speed applications

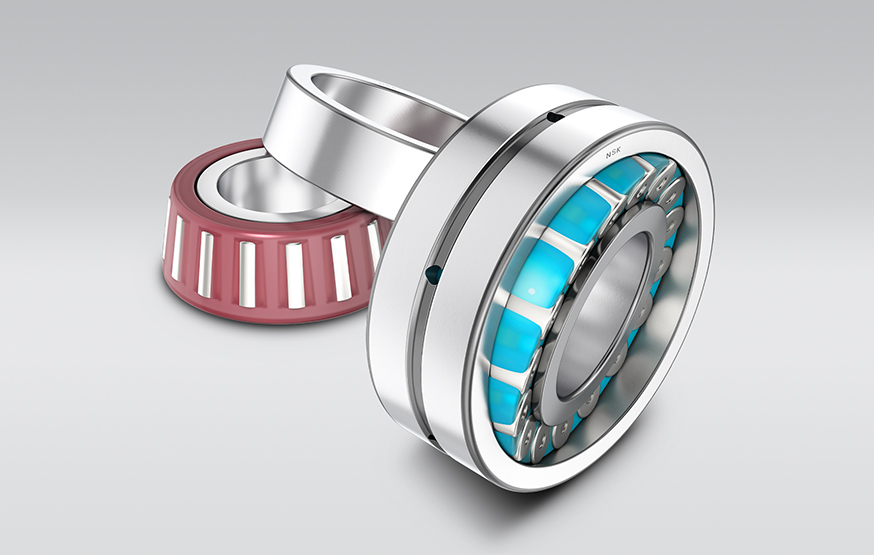

- Available for spherical roller bearings, deep groove ball bearings, and tapered roller bearings

Operating Benefits

- Extended bearing performance with continuous supply of clean lubricant

- Eliminates the need for relubrication, reducing maintenance costs

- Eliminates risk of grease leakage, promoting clean operating environments

- More than twice the operating life of grease-lubricated bearings in water or dust-contaminated environments

- Ideal solution for remote or restricted access areas

Fields of Application including

- Agricultural machinery

- Concrete and cement

- Conveyors and material handling

- Food and beverage processing equipment

- Mining and construction machinery

- Paper making machinery

- Semiconductor manufacturing equipment

- Steel making machinery

Technical Tools

eStore & Online Catalog

*To order online, you must have a registered account.

Share