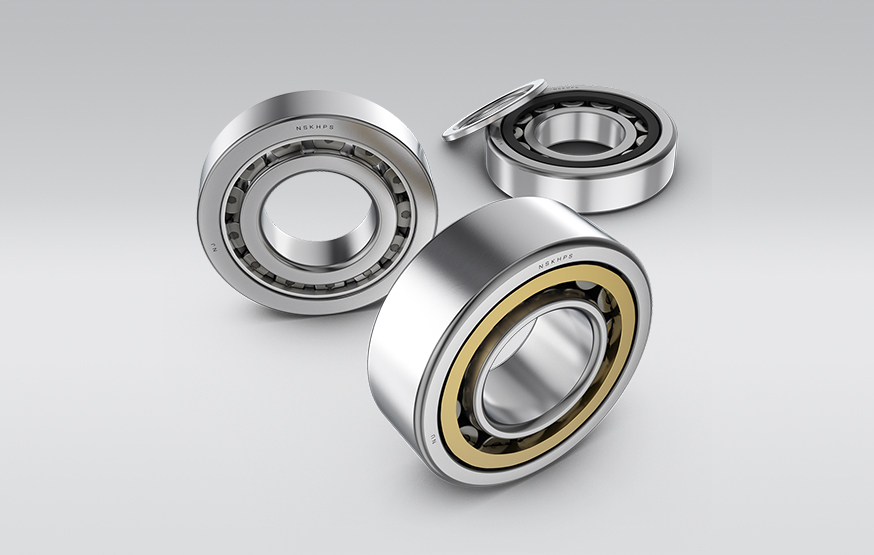

Design Features

- Optimized, high-capacity internal design for NU, NJ and NUP bearing types

- NU type - allows axial displacement in both directions

- NJ type - locates the shaft axially in one direction

- NUP type - locates the shaft axially in both directions

- Available with machined brass, pressed steel and polyamide resin cage designs to suit a wide range of operating conditions

- Special chemical resistant L-PPS resin cages for compressor also available

- Special roller crowning reduces edge loading

- For dimension series 2, 22, 3, 23

- Available for bore diameters from 25 to 220 mm

- With C-Normal, C3 and C4 clearance

Operating Benefits

- Dramatically increased bearing life compared to conventional designs, as high as twice among larger sizes

- As much as 23% higher basic load rating

- High strength and maximum rigidity for high loads and high speeds

- Improved lubricant flow promotes lower running temperature and low noise

- Higher permissible misalignment

Fields of Application including

- Concrete and cement

- Electric motors

- Fans and blowers

- Gearbox and drives

- Mining and construction machinery

- Paper making machinery

- Pumps and compressors

- Oil and gas machinery

- Steel making machinery

- Wind turbines

Share