NSK Press Release

NSK Europe Ltd.

Marketing & Communications Department

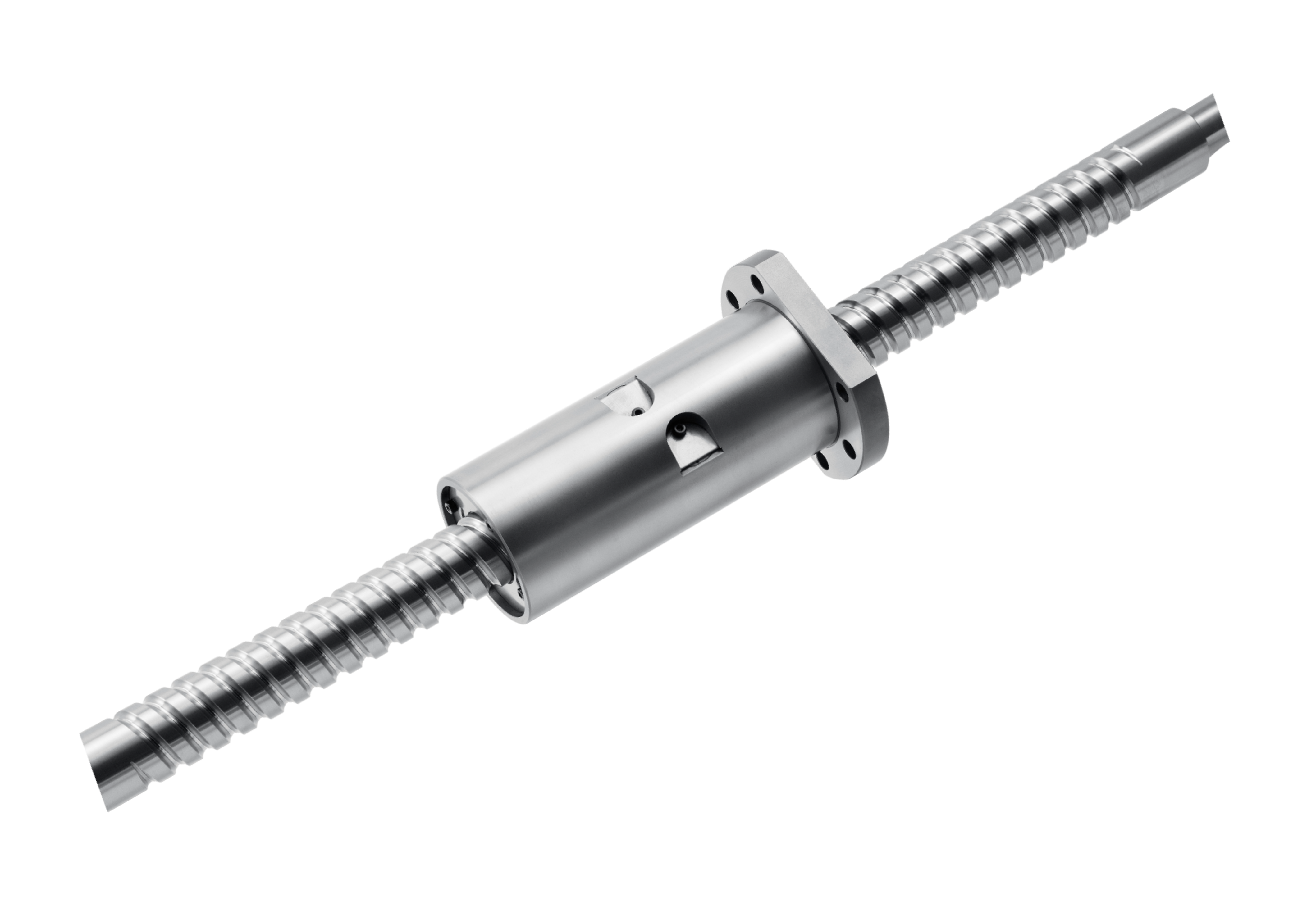

NSK Develops Low-Friction Ball Screw for Machine Tools

NSK has developed MT-Frix, a low-friction ball screw designed for machine tool applications.

The newly developed product.

Already available for purchase, the new ball screw offers a significant reduction in dynamic friction torque, solving a major headache frequently faced by companies within the sector. It does this whilst also maintaining nut rigidity, reducing heat generation and allowing for more sustainable machine tool accuracy and increased energy savings.

The reduction in torque friction was made possible by NSK’s analytical technology, which was used to clarify the contact condition between the ball and groove in order to develop optimal internal specifications. NSK then used those specifications to reduce dynamic friction torque whilst maintaining nut rigidity without altering the dimensions of the ball screw. This, in turn, enabled significant heat reduction.

Additionally, MT Frix is also able to sustain high positioning accuracy and offers a reduction of up to 50% in the CO2 emissions caused by dynamic friction torque.

Background and Development

MT Frix presents a solution to several challenges faced in the machine tools sector. Within the industry, ball screws are found mounted on the linear drive units of machine tools and are responsible for positioning the machining tools and workpieces.

In recent years, there has been growing demand for ball screws to offer higher positioning accuracy and increased energy savings. One issue standing in the way is that, when a ball screw is driven, it generates heat due to dynamic friction torque (this being the torque caused by friction generated when a ball screw rotates) and the screw shaft undergoes thermal expansion, which in turn reduces the positioning accuracy.

One way to prevent accuracy loss due to heat generation is forced cooling (which generally involves cooling the generated heat with an auxiliary device), but the use of such a device causes a rise in energy consumption. Therefore, in order to achieve both high precision and energy savings, it is necessary to reduce the dynamic friction torque itself.

However, with conventional technology, when the dynamic friction torque is reduced, the rigidity (meaning the resistance to deformation due to external load) also declines, making the ball screw’s nut more likely to experience displacement. This can in turn result in reduced machining accuracy. As a result, NSK wanted to find a way of reducing dynamic friction torque while maintaining rigidity.

This is where the company’s analytical technology came in. It was used to clarify the contact condition between the ball and groove, which made it possible to develop optimal internal specifications. As a direct result, dynamic friction torque was reduced without impacting nut rigidity or the dimensions of the ball screw.

Features and Benefits

In conclusion, MT Frix offers a series of impressive features and benefits. Compared to conventional alternatives it offers a significant reduction in both dynamic friction torque (up to 50%) and heat generation (up to 40%) without any change in nut rigidity.

It also offers sustained high positioning accuracy because, as a direct result of reduced heat generation, the amount of axial elongation is reduced by up to 40% compared to conventional products, reducing the deterioration of positioning accuracy.

Finally, it allows for significant energy savings. Indeed, compared to conventional alternatives CO2 emissions caused by dynamic friction torque have been reduced by up to 50%.