철강 설비는 원료 야드에서 시작해서, 제강 공정, 압연 공정, 제품 정수 공정 등 공정의 시작부터 끝까지 다양한 시설이 있으며, 각 시설특성에 따라 서로 다른 유형의 베어링을 사용하고 있습니다. 그리고, 이 베어링은 "철분진", "물"과 "열”등 철강 설비 특유의 환경에서 사용되는 것은 물론, “극도의 하중 + 진동과 충격", “극 저속에서 고속 + 급 감속“ 등 매우 열악하고 가혹한 환경이 동시에 발생합니다.

NSK는 장치산업의 대표격인 철강산업의 주요이슈인 "안정적인 가동과 생산성 향상"에 기여함을 목표로 합니다.

- 높은 수준의 베어링 설계 기술

- 베어링 재료, 윤활, 분석 기술 등을 비롯한 다양한 측면에서의 지속적인 연구 개발

NSK는 ISO 표준 베어링에서 부터, 자체 개발한 고성능 전용 베어링에 이르기까지, 철강 설비 전부문에 사용되는 다양한 종류의 베어링을 폭넓게 라인업하고 있습니다. 또한 현재 철강 업계의 고부가가치 제품에 대한 필요성, 철강산업의 환경친화적 접근에 대응하기 위해 새로운 접근을 시도하고 있습니다

NSK 경험 & 기술

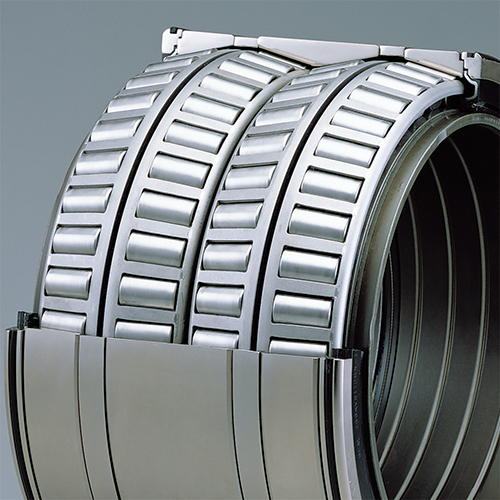

붉게 달궈진 철을 얇고 길게 성형하는 압연 공정은 철강 설비 중에서도 대표적인 공정이자, 최종 제품의 품질에 크게 영향을 미치는 중요한 과정이기도 합니다. 이 공정에서 양쪽 부분은 주로 4 열 테이퍼 롤러 베어링이 사용되고 있습니다. 베어링 사용 조건 역시 철강 설비의 대표격인, 무게 하중 이외에 냉각수와 스케일에 노출되는 열악한 환경에서 사용됩니다.

NSK는 오래전부터 4 열 테이퍼 롤러 베어링의 수명 연장을 위한 연구와 도전을 계속하고 있습니다. 1970 년대에 세계 최초로 물이나 스케일의 침입 방지를 목적으로 오일씰을 장착한 "밀봉식 4 열 테이퍼 롤러 베어링"을 개발하고 비약적으로 베어링 수명 연장을 실현시켰습니다. 이후에도 밀봉 베어링용 윤활제를 발표하고 1990 년대에는 내부 디자인을 향상 정격 하중을 크게 향상시킴과 동시에 스케일에 강한 신소재를 개발했습니다. 최근에는 규모뿐만 아니라, 냉각수에 강한 신소재를 개발하여 왔습니다.

앞으로도 고객 만족, 신뢰받는 NSK을 목표로 고객과 함께할 것을 약속 드립니다.

Documents

제품소개

연속주조 자유측용 장수명 고기능 실린더 로울러 베어링

취급성을 향상한 장수명 고기능인 실런더 로울러 베어링입니다.

장수명 내수 그리스 밀봉형 4열 테이퍼드 로울러 베어링

물이 혼입되는 가혹한 환경에서 사용되는 워크롤러 베어링의 장수명화를 실현했습니다

특징:

- 밀봉설계 및 부하능력 최대화

- 윤활성능 향상 (내수 그리스 개발)

- 기존 제품 대비 2배 이상 장수명

High-performance SNN Series plummer blocks are highly rigid and easy to handle. They contain NSK's tough spherical roller bearings, which have high load capacity, low temperature rise and high-strength cages.

NSK successfully developed the NSKHPS series of spherical roller bearings, which provides a longer service life and higher limiting speeds, by employing leading-edge materials and technology in combination with years of cultivated experience and technical know-how.

Features:

- Bearing life increased by twofold (increased dynamic load rating by 25%)

- Limiting speed increased by 20%.

Full-complement cylindrical roller bearings for crane sheaves that are equipped with tight seals intended to prevent intrusion of foreign matter.

Features:

- Contact seals provide improved sealing capability to prevent the intrusion of foreign matter and water.

- Large radial and axial capacity is retained for high capacity performance.

- Phosphate coating provides improved corrosion resistance.

- Grease can be replenished through the use of inner ring lubrication holes.

- The number of bearing peripheral parts required for mounting the bearing has been reduced through the use of snap rings on the outer ring.

NSK, the first company in the world to offer sealed roll neck bearings, now offers the Extra-Capacity Sealed-Clean series of roll neck bearings.

Features:

- Newly designed internal specifications and a new compact seal result in a high-capacity design that provides increased bearing capacity.

- The new main seal and seal holder are designed for easier mounting and dismounting.

- The new bore seal prevents the buildup of negative pressure as a measure against water infiltration.

- Bearing material is made from super-TF steel, which contributes to enhanced bearing life under conditions of contaminated lubrication.

Molded-Oil bearings are lubricated with oil-impregnated solid material, which is contained within the bearing. Oil slowly seeping from this solid lubricant material provides ample lubrication to the bearing for extended periods.

Features:

- Designed to prevent water and other liquids from washing out the lubricating oil while preventing dust and other contaminants from getting inside the bearing.

- Low-torque achieved by packing the bearing with oil-impregnated solid material after bearing surfaces have undergone a special surface treatment.

- Protect the working environment by eliminating stray oil mist or leakage.

- High-speed capability enabled through optimal composition of the solid lubricant material and methods used for the molding process.

Through the application of NSK's innovative concepts, the EM series bearing has a greater number of larger rollers than that of a conventional bearing. Furthermore, the optimally designed one-piece cage offers high rigidity and low-wear performance.

EW Series Bearing

Features:

- Bearing life increased by approximately twofold.

- Noise and vibration levels reduced by 60 to 70 percent.

- Cage strength has been increased by one and a half to twofold.

- Limiting speed increased by 10 to 25 percent.

EM Series Bearing

Features:

- Bearing life increased by approximately twofold.

- Noise and vibration levels reduced by 40 to 50 percent.

- Cage strength has been dramatically improved.

This innovative roll unit bearing provides both low-torque performance and high-sealing capability

Features:

- A newly developed seal structure helps to ensure low-torque performance.

- The seal structure, which consists of a labyrinth seal and a side seal, ensures excellent sealing performance.

- Prepacked with grease that offers superior durability and water resistance to ensure longer, maintenance-free performance.

NSK developed a series(S-Type)of tough, sealed-clean roller bearings for chain conveyors that must operate under severe conditions They feature newly designed seals (Japanese Utility Model pending) with exceptional effectiveness. These seals, combined with specially formulated grease, assure long life with no maintenance, even at high temperatures and in the presence of water and scale Also, the inner and outer rings are made of case-hardened steel to make them resistant to shock loads for rugged operating conditions, S-Type chain-conveyor bearings are the solution to maintenance problems.

This series of the Sealed-Clean bearing helps prevent grease from leaking onto surrounding equipment, and helps reduce maintenance costs.

Features:

- Specially designed contact seal offers excellent sealing performance against dirt and debris.

- Packed with grease that has been developed for high-temperature and high-pressure operating conditions, for high sealing performance.

- One-piece design with fastening ring on the inner ring facilitates easier handling and mounting.

Three types of roller bearings have been developed for use in CCM guide rolls by fusing NSK's years of experience with leading-edge technology.

Features:

- Split cylindrical roller bearing unit for easy bearing replacement.

- Cylindrical roller bearing with aligning ring for preventing differential slip and misalignment.(Free Side)

- SWR bearing for dramatically improved wear resistance.