Spherical Roller Bearings

Overview

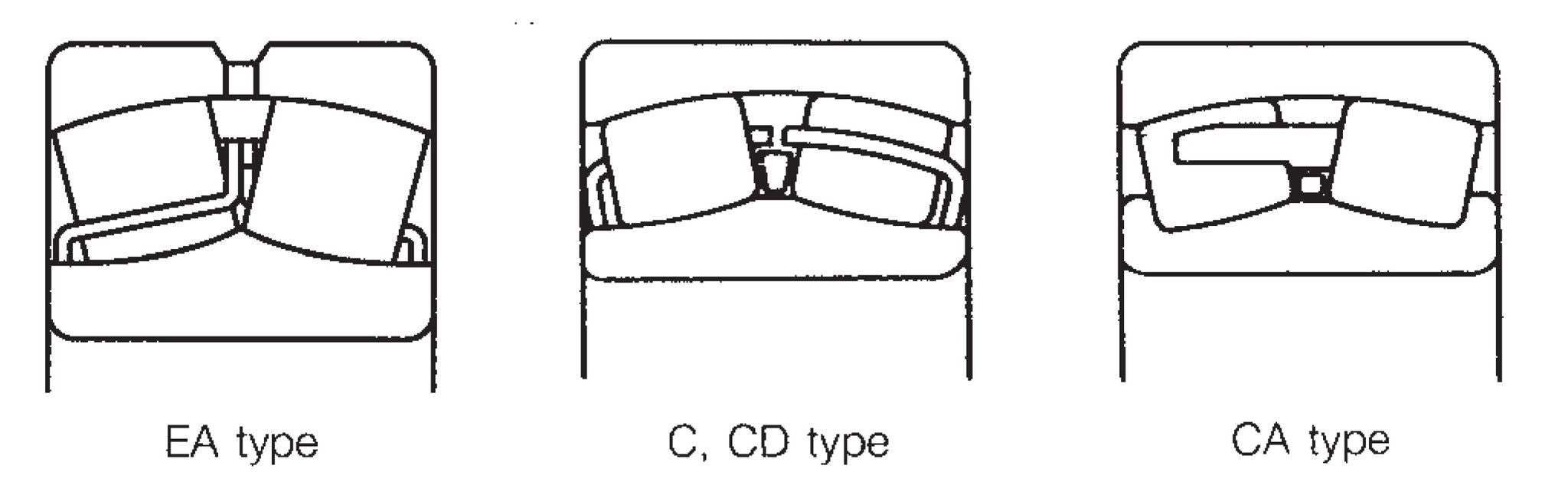

Spherical roller bearings are available in EA, C, CD, and CA types designed for high load capacity. Types EA, C, and CD have pressed steel cages, while CA uses machined brass cages. All EA types are high-performance standard NSKHPS Series bearings.

NSKHPS Series bearings have especially high load capacity, high limiting speeds, and excellent performance at temperatures up to 200°C.

Designations suffixed with “E4” have an oil groove and holes on the outer ring. Since the depth of the oil groove in these bearings is limited, we recommend using an oil groove in the housing bore as well.

Features

- Self-aligning

The bearing automatically compensates for deviation from the shaft center and bending in the housing or shaft, preventing excessive force from being applied to it. - Support for all types of loads

Spherical roller bearings sustain radial loads, axial loads in both directions, and combined loads. - For fixed-end or free-end

Applications

- High load

Suited for equipment facing large radial loads, heavy loads, and impact loads - Mining equipment (powdering machines, vibrating screens, conveyors, etc.), gearboxes, air preheaters, extruders, centrifugal separators, construction machinery, steelmaking machinery, papermaking machines

FAQs

Catalogs

Search our full listing of catalogs for more details.

2D/3D CAD Data

Download 2D & 3D CAD model files and spec. sheets for NSK products through PARTcommunity.

This free service is provided by CADENAS GmbH.