Friction Material Development

Friction Material Development for Future Vehicle

Friction Material Development

Groove Design for EV and HEV

Paper based friction material used in wet friction application consists of composite paper with high functioning fibers and fillers and resin, and has porous and elastic structure to be operated in an oil submerged environment.

NSK-Warner has continuously developed advanced wet friction materials through R&D activities in ingredients, processes, and analyses, to satisfy such a customer demand change as progress of engine, transaxle, oil, and electrification for EV and HEV.

To get innovative friction materials for future,

Enlarged image of friction material

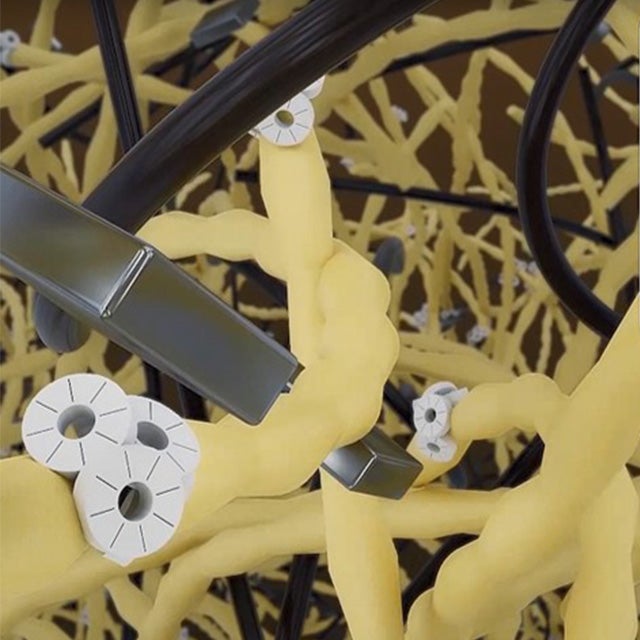

X-ray Scan for Friction Material

NSK-Warner has kept on R&D activities widely and deeply in new ingredients, properties, processes and mechanisms.

NSK-Warner has challenged to control material structure in micron-scale order by using a cutting-edge technologies.

NSK-Warner also has focused on analysis of oil flow in friction interfaces by both experiments and computer calculations to co-ordinate friction phenomena and friction material design.