Philosophy & Achievements / Core Technologies

Philosophy & Achievements

NSK has relentlessly pursued innovative technologies and focused on improving quality in order to contribute to a safer, smoother society and to protect the global environment, in line with its corporate philosophy. The foundation that underpins those technologies consists of tribology, materials, numerical simulation and mechatronics, which are NSK’s Core Technologies.

Then there is manufacturing engineering, another important technology and strength of NSK that gives shape to our Core Technologies.

The technologies and products that have been created based on our Core Technologies are contributing both to the development of industry across the world and to people’s abundant lifestyles.

NSK will continue to engage in advanced technological development and provide highly functional, high-quality products that meet market needs in the years to come.

In an effort to contribute to a safer, smoother society and to protect the global environment, as spelled out by NSK corporate philosophy, NSK strives to accurately determine customer and societal needs, and develop environmentally friendly products and technologies that utilize the Company’s Core Technologies: Tribology (friction control technology), Materials, Numerical Simulation, and Mechatronics.

By developing and bringing to market sophisticated and innovative new products in a timely manner, NSK contributes to creating a safer, smoother society while also helping save energy and reduce carbon dioxide emissions.

Core Technologies

Tribology

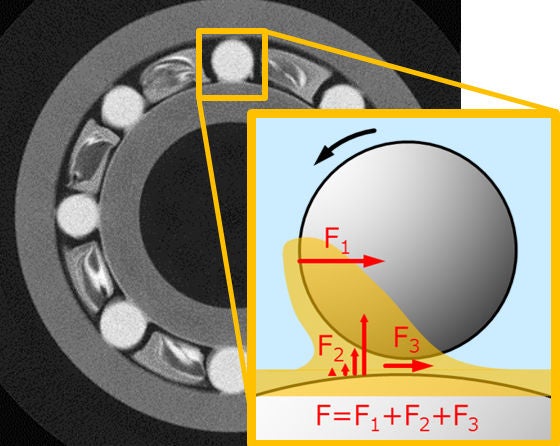

Friction on the bearing’s ball surface

Studying, Clarifying and Controlling Friction

Tribology is the study of friction and wear of contact surfaces in relative motion, such as rotating parts that endure enormous forces with a thin oil film.

Severe operating conditions are mitigated through lubrication and surface treatments developed by NSK, resulting in superior performance for applications requiring low friction, high-speed rotation, quiet operation, or enhanced durability.

Materials

Bearings utilizing ceramics and resins

Unrelenting Pursuit of Performance Durability and Reliability

Materials research and development affects nearly every aspect of product performance.

We are constantly pursuing cost and productivity while meeting ever- evolving demands for improved functionality, durability, and reliability through technologies that utilize metals, polymers, and ceramics with optimized material composition and heat treatment conditions.

Numerical Simulation

Example of bearing grease flow analysis

Simulated Recreation in Cyberspace to Predict Performance

In the past, accuracy and reliability in product development were achieved with experience-based design and longer testing periods.

NSK's simulation technology allows virtual validation to accelerate design and production. Extreme conditions or innovative designs that defy previous expectations can also be evaluated and analyzed.

Mechatronics

Active Caster

Technology Supports People for a Convenient, Safe and Comfortable Future

Mechatronics integrates machine element technology with control technology.

By combining bearings, ball screws, and linear guides, together with motors, sensors, and computers, greater mechanical functionality is elicited with computer control. This technology enables new functions and performance in a range of industrial machinery,

automotive, and biomedicine applications. It also contributes to greater reliability, as well as to convenience and safety in daily life.

Manufacturing Engineering

Cheonan Plant in South Korea

Giving Shape to Core Technologies

Contributing to the environment and heightening safety and security through our Core Technologies requires something to breathe life into these technologies. In addition, it is essential to consistently manufacture products with high quality.

NSK tackles these issues by applying smart technology to its equipment, utilizing lot, and optimizing its overall production framework while it works to realize the creation of smart factories that economize on space, save on energy, and reduce labor requirements.

Read more