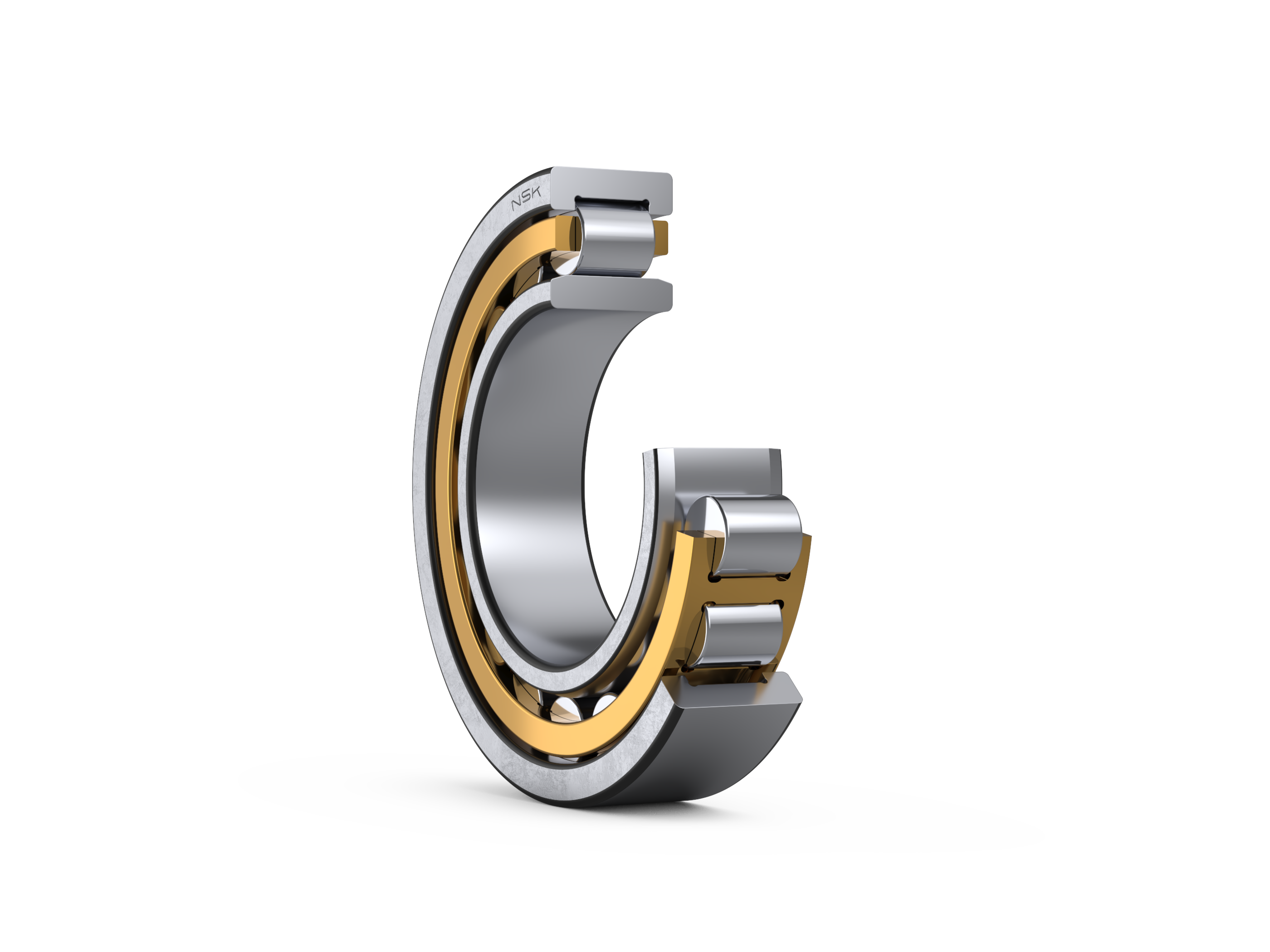

Cylindrical Roller Bearings

Overview

Cylindrical roller bearings (CRBs) have a simple structure of cylindrical rollers in linear contact with the raceways. They offer high load capacity under primarily radial loads. Low friction between the rollers and ring ribs makes these bearings suited for high speed rotation.

Single-row bearings are designated as NU, NJ, NUP, N, or NF, while double-row bearings are designated as NNU or NN, depending on if side ribs are used. All types allow the inner and outer rings to be separated.

Some CRBs used as free-end bearings have no ribs so that the rings can move axially relative to each other. When the inner or outer ring has ribs on both sides and the other ring has a rib on one side, these bearings can take some axial load in one direction.

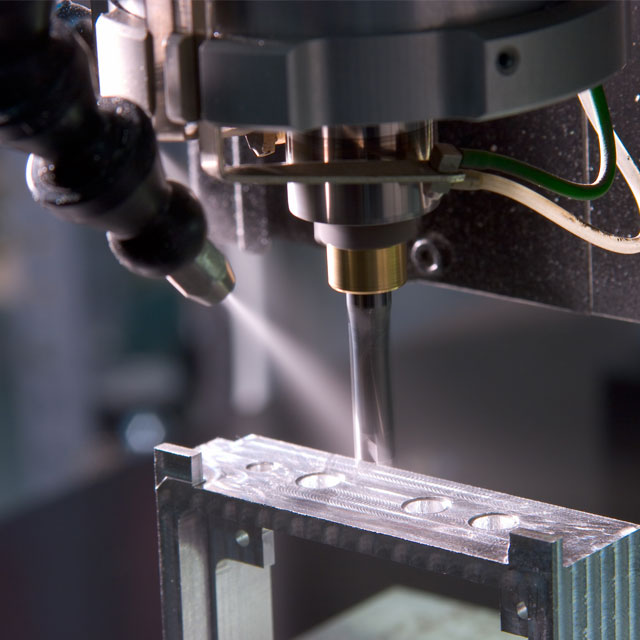

Double-row cylindrical roller bearings have high radial rigidity and are used primarily for the main shafts of precision machine tools. Cages are typically made of pressed steel or machined brass, but molded polyamide resin cages are used for some models.

NSK offers a variety of CRB types to suit your needs.

Types of Cylindrical Roller Bearings

NU, N, NNU, NN: Suitable as free-end bearings.

NJ, NF: Can sustain limited axial loads in one direction.

NH, NUP: Suitable as fixed-end bearings. NH types are comprised of a NJ-type CRB with a HJ-type L-shaped thrust collar.

Product List

FAQs

Catalogs

Search our full listing of catalogs for more details.

2D/3D CAD Data

Download 2D & 3D CAD model files and spec. sheets for NSK products through PARTcommunity.

This free service is provided by CADENAS GmbH.