Business Continuity Management (BCM)

NSK’s Approach

NSK’s basic policy is to place the highest priority on ensuring the safety of human life, to respond to disasters in collaboration with society and to prevent disruptions to essential operations and to promptly resume operations in the event of a suspension. To shorten the time required to resume production, we have formulated a Business Continuity Plan (BCP) that includes thoroughgoing disaster mitigation measures to minimize damage at the time a disaster occurs and measures to shorten the recovery period. The BCP also includes steps to ensure sufficient inventories to meet our responsibility to supply products to customers for a period longer than required to resume production.

System

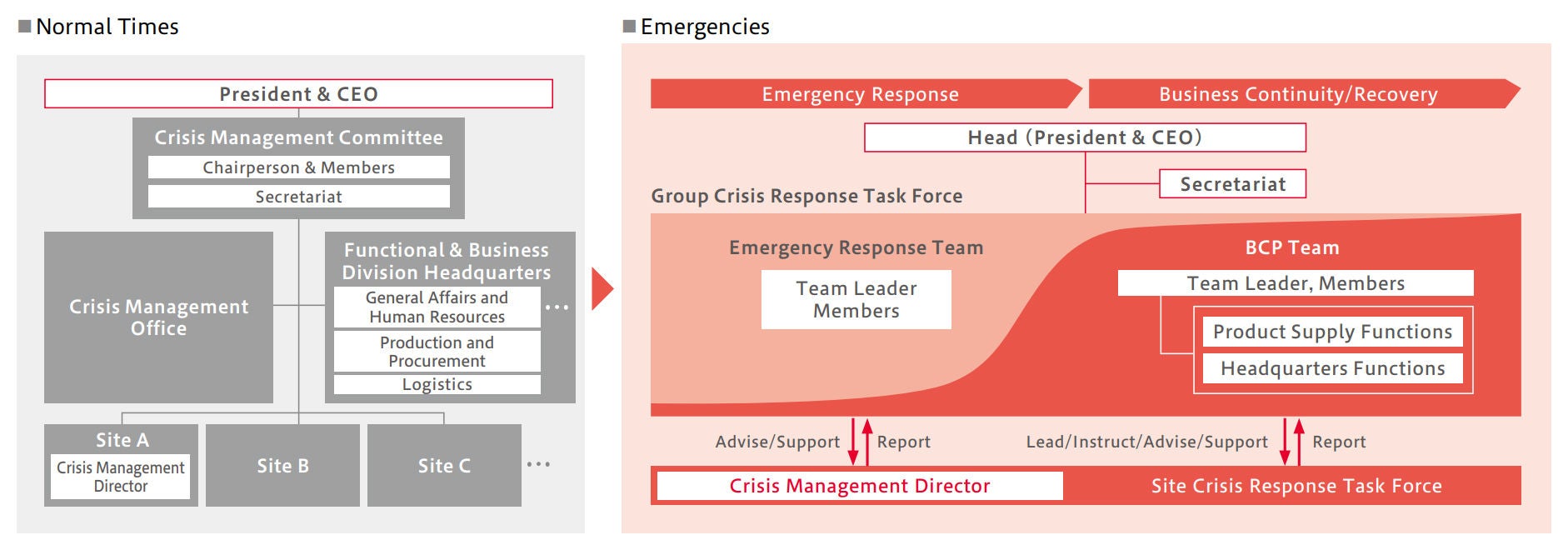

We have established the permanent Crisis Management Committee under the direct control of the CEO. This Committee is charged with the responsibility of overseeing business continuity management initiatives. In this manner, we have put in place a system for directing and controlling preparations and contingency responses for such incidents as natural disasters, the outbreak of infectious diseases, major accidents/incidents, and other risks that might materialize. In addition, such organizations have been established in each region outside Japan to oversee business continuity management. The Crisis Management Committee will work with these organizations to deal with risks when they emerge.

Crisis Management Structure

Targets and Performance

Mid-Term Management Plan 2026 (MTP2026) Targets, with Targets and Performance for Each Fiscal Year

| Policy | Development of group crisis management systems | BCP formulation and effectiveness enhancement | |

|---|---|---|---|

| MTP2026 | Targets |

|

|

| FY2022 | Targets |

|

|

| Performance |

|

| |

| FY2023 | Targets |

|

|

Initiatives

BCP Establishment

Setting Recovery Time Objectives

Recovery time objectives are set so as to enable a resumption of product supply to customers even after a crisis occurs. To ensure recovery within the target period, the NSK Group promptly implements measures to thoroughly minimize damage in the event of a disaster. By reducing the recovery period and securing the minimum inventory required, we will be able to continue supplying products. In anticipation of unforeseen damage and difficulties for recovery within the target period, we are in a state of preparedness so that business activities can be resumed using alternative functions.

Specific Initiatives

At NSK sites, including the head office and Group companies in Japan, we have been preparing for potential emergencies. These efforts include creating emergency organizational structures, establishing response procedures, and assembling useful tools. We also confirm the viability of the preparation through regular drills and address issues that emerge during the drills to make improvements. We are also working to improve BCP effectiveness in the event of a major disaster such as a large-scale earthquake. This is being done by preparing measures to minimize damage, securing emergency communication channels, establishing a reporting system, preparing for large-scale power outages, and ensuring backups for IT infrastructure.

Turning to regions outside Japan, we are formulating BCPs for our business sites based on the assumption of region-specific risks and verifying the effectiveness of the BCPs we have developed.

≪Initiatives in FY2023≫

- Conducting Self-Inspections of Business Continuity Management Systems as well as Crisis Management and BCPs

As far as its business continuity management systems are concerned, NSK has prepared inspection sheets based on the business continuity guidelines issued by the Cabinet Office of Japan. The Company conducts periodic self-inspections of regional headquarters functions and identifies issues in all regions. Moreover, we evaluate the current status of crisis management and BCP measures at each business site based on our own guidelines, and clarify issues so that we can respond promptly in the event of an emergency.

- Strengthening Emergency Response and Business Continuity Measures through Training and Workshops

Utilizing our Fukushima Plant as a model case, we published a manual in FY2022 intended to promote a shift away from a headquarters-led approach and encourage each location to conduct training on an independent basis. In this manner, we are working to strengthen our initial response capabilities in emergencies. In FY2023, plans are in place to conduct voluntary training at all locations in Japan and locations outside Japan with earthquake risks. Regarding business continuity, NSK believes it is important to conduct risk assessments of resources such as people, equipment, and infrastructure, identify gaps against recovery targets, and formulate implementation plans for countermeasures in each division. Starting in FY2023, we will hold workshops at key locations to formulate implementation plans for countermeasures, working to improve the level of our business continuity capabilities.