Episode 02

Total predictive maintenance: AI + IoT + vibration experts

Developing NSK's condition monitoring ecosystem

Meet the Team

-

On Assignment in Germany at B&K VibroKunihiko, Chief Technology AdvisorNew graduate hireKunihiko joined NSK after finishing graduate school. After conducting fundamental research for MEMS sensors and the development of smart bearings in Japan, he moved to San Jose, California on assignment for three years where he worked in new business development. After returning to Japan, he worked to combine both theory and machine learning to develop algorithms for vibration diagnostics at the CMS Development Center. His current assignment is in Germany as Chief Technology Advisor for Brüel & Kjær Vibro GmbH (B&K Vibro) where he oversees technology roadmaps, project management, and technical collaborations between B&K Vibro and NSK.

On Assignment in Germany at B&K VibroKunihiko, Chief Technology AdvisorNew graduate hireKunihiko joined NSK after finishing graduate school. After conducting fundamental research for MEMS sensors and the development of smart bearings in Japan, he moved to San Jose, California on assignment for three years where he worked in new business development. After returning to Japan, he worked to combine both theory and machine learning to develop algorithms for vibration diagnostics at the CMS Development Center. His current assignment is in Germany as Chief Technology Advisor for Brüel & Kjær Vibro GmbH (B&K Vibro) where he oversees technology roadmaps, project management, and technical collaborations between B&K Vibro and NSK. -

CMS Platform Development GroupSatoshi, Development Lead

CMS Platform Development GroupSatoshi, Development Lead

New graduate hireAfter completing graduate school, Satoshi joined the research department of the NSK Linear Technology Center where he conducted technology development and vibration analysis for ball screws. In 2017, he moved to the CMS Development Center, where he worked on developing fundamental technologies and algorithms for condition monitoring. Satoshi currently oversees development of CMS platforms, working to improve the cloud technologies and generative AI powering the NSK CMS ecosystem. He also leads in-house design brainstorming workshops, helping fellow NSK employees to create products that maximize value for customers. -

CMS Development Department, Industrial Machinery Business Division HQArisa, MarketerMid-career hireArisa joined NSK in 2022 after previously working for an apparel trading company, a manufacturer, and an IT company. Her current role is in NSK's Industrial Machinery Business Division HQ, where she works to market CMS technologies. Arisa works to acquire new customers by publicizing NSK's CMS offerings through the company website, social media, and online advertising. As this project involves close collaboration with B&K Vibro to expand the CMS market, Arisa plans and implements promotions strategically, working to foster deeper relationships with customers through effective marketing.

CMS Development Department, Industrial Machinery Business Division HQArisa, MarketerMid-career hireArisa joined NSK in 2022 after previously working for an apparel trading company, a manufacturer, and an IT company. Her current role is in NSK's Industrial Machinery Business Division HQ, where she works to market CMS technologies. Arisa works to acquire new customers by publicizing NSK's CMS offerings through the company website, social media, and online advertising. As this project involves close collaboration with B&K Vibro to expand the CMS market, Arisa plans and implements promotions strategically, working to foster deeper relationships with customers through effective marketing.

Advancing CMS to Support Predictive Maintenance in Manufacturing

As workforces continue to shrink and age, skilled workers are increasingly in short supply. In this environment, unexpected downtime can spell disaster for manufacturers, so early detection of abnormalities in machinery and production equipment is crucial. This is the core concept of “predictive maintenance.”

In 2021, the NSK Group addressed this need by acquiring B&K Vibro, a leading company specialized in the rapidly-growing CMS market. Now, development is underway for a comprehensive condition monitoring ecosystem that combines B&K Vibro’s proven monitoring technology for rotating machinery with NSK's diagnostics for linear motion components and expert vibration analysts. This one-stop solution utilizes wireless sensors and cloud services to allow machine data to be collected and analyzed in real time, enabling abnormalities to be detected with high accuracy and providing advance warning of potential problems before breakdowns occur.

NSK is also leveraging AI and machine learning to further advance its predictive maintenance technology, enabling it to better respond to increasing demand for automation, smart factories, labor-saving, and environmental protection.

Development Timeline

-

December 2020–March 2021

B&K Vibro joins the NSK Group

In March 2021, B&K Vibro is integrated into the NSK Group to strengthen the CMS business. B&K Vibro's technologies, established customer base, and extensive data help NSK to advance predictive maintenance and drive automation, labor savings, and smart factories.

-

January 2024

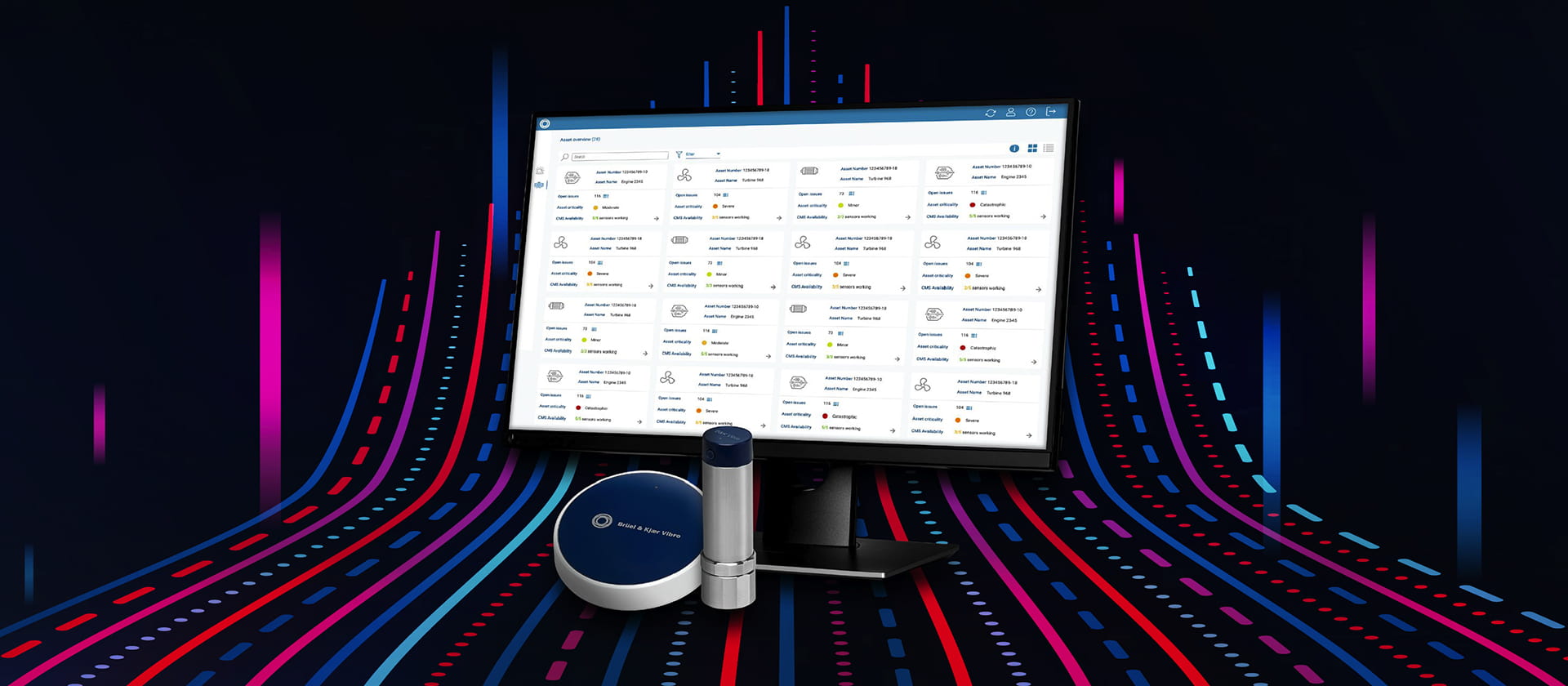

Wireless diagnostic device released in Japan

NSK releases a pocket-sized wireless solution that allows technicians to easily check the status of equipment from anywhere via the cloud. NSK's diagnostic indicators, developed based on years of expertise, are checked by AI to detect equipment abnormalities at an early stage.

-

April 2025

Positioning CMS for the future

NSK's organizational structure is upgraded to further accelerate the development and deployment of CMS and PLM*1technologies.

-

September 2023

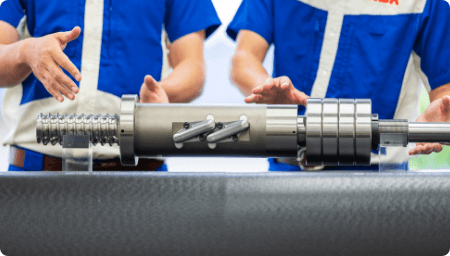

Development of CMS for linear motion products

With its deep technical expertise in tribology, NSK provides exclusive diagnostic technology not only for its signature bearings, but also for linear motion components including ball screws and linear guides. NSK diagnostics integrated into B&K Vibro’s condition monitoring systems help contribute to safe operations and higher maintenance efficiency.

-

October 2024

New frontiers in CMS

An upgrade to existing wired condition monitoring systems (VCM-3) provides a data link to cloud services. NSK's advanced diagnostic AI and diagnostic experts are now able to work in tandem to provide the advanced condition monitoring required by industrial machinery.

※1Product Lifecycle Management: Considering a product's manufacture and usage throughout its entire lifecycle. By incorporating PLM and CMS through strengthened services in maintenance and repairs, NSK serves as a trusted partner at every step of a product’s journey.

-

December 2020–March 2021

B&K Vibro joins the NSK Group

In March 2021, B&K Vibro is integrated into the NSK Group to strengthen the CMS business. B&K Vibro's technologies, established customer base, and extensive data help NSK to advance predictive maintenance and drive automation, labor savings, and smart factories.

-

September 2023

Development of CMS for linear motion products

With its deep technical expertise in tribology, NSK provides exclusive diagnostic technology not only for its signature bearings, but also for linear motion components including ball screws and linear guides. NSK diagnostics integrated into B&K Vibro’s condition monitoring systems help contribute to safe operations and higher maintenance efficiency.

-

January 2024

Wireless diagnostic device released in Japan

NSK releases a pocket-sized wireless solution that allows technicians to easily check the status of equipment from anywhere via the cloud. NSK's diagnostic indicators, developed based on years of expertise, are checked by AI to detect equipment abnormalities at an early stage.

-

October 2024

New frontiers in CMS

An upgrade to existing wired condition monitoring systems (VCM-3) provides a data link to cloud services. NSK's advanced diagnostic AI and diagnostic experts are now able to work in tandem to provide the advanced condition monitoring required by industrial machinery.

-

April 2025

Positioning CMS for the future

NSK's organizational structure is upgraded to further accelerate the development and deployment of CMS and PLM*1technologies

※1Product Lifecycle Management: Considering a product's manufacture and usage throughout its entire lifecycle. By incorporating PLM and CMS through strengthened services in maintenance and repairs, NSK serves as a trusted partner at every step of a product’s journey.

The Excitement of Agile Development and Global Collaboration

What are your respective roles in this project to develop a comprehensive NSK CMS ecosystem?

Kunihiko

KunihikoThis project is being driven by a global team based in Germany and Japan. I’m responsible for managing the development team and devising the development roadmap in collaboration with worksites around the world. My other important mission is to listen to the needs of our global customers and address these in our plans.

Satoshi

SatoshiI’m primarily responsible for developing and expanding product features. To meet the needs of our customers, we’ve been using agile development to repeatedly test small-scale prototypes and build optimized solutions.

Arisa

ArisaI’m in charge of overall marketing and product branding as we work to introduce our solutions. This involves working to increase product awareness and attract new customers through our websites and advertisements. As the parts of the project come together, the rollout to market is my time to shine!

How did development start?

Kunihiko

KunihikoAt NSK, we want to know all the details about our customers’ equipment so that we can best meet their needs. We’ve been developing CMS technologies with this in mind to enhance our aftermarket presence. However, implementing CMS as a service requires a wide variety of resources, including sensors, monitoring devices, and databases that reflect the advice and suggestions received from our customers. B&K Vibro, with its strengths in CMS for wind turbines and years of service data, has been a great asset to NSK. Combining our technologies and capabilities, we’re developing a comprehensive solution that suits a wide range of industries.

What is your biggest takeaway from this project?

Kunihiko

KunihikoThe key point and challenge of this project has been to apply B&K Vibro's CMS technologies, which have a proven track record in wind power generation, to other industries by leveraging NSK's knowhow and data on mechanical components. As this is a new undertaking, the project is a constant process of trial and error.

Satoshi

SatoshiThere is no "right answer" when it comes to developing new systems. Our approach has been to provide a minimum viable product (MVP) as a small-scale prototype and test it in the field at a customer's plant. This allows us to quickly identify any issues and make improvements, advancing our solutions step by step.

Arisa

ArisaAnother key point is that the overseas sites of NSK and B&K Vibro are working together as one team. Although we’ve faced some communication difficulties as the project members all come from different backgrounds, we are working together to overcome these challenges one by one. I personally try to make sure we are sharing enough information and communicating proactively to ensure mutual understanding and develop more effective marketing strategies.

Kunihiko

KunihikoThe IT infrastructure at different NSK sites can also vary. This can make communications tricky; however, Arisa helped us create a shared platform for the project that made it possible for team members across different regions to share information smoothly. This is true in product development as well—the systems we want to create differ by country, and developing locally tends to result in services that only match local needs. Having a shared platform has helped to create a sense of cooperation towards our collective goal of creating a CMS ecosystem that can be used anywhere in the world.

Satoshi

SatoshiBuilding on this I think a key point is that we are looking beyond on-premise needs to build CMS services that can fully utilize the power of the cloud. This focus makes sense in terms of our global ambitions. Since this is one of NSK's first large-scale cloud deployments, we are charting new territory.

What are some of the unique ways that NSK is using AI in this project?

Arisa

ArisaBoth NSK and B&K Vibro have equipment diagnosticians who are experts in vibration. By combining their knowledge with AI, we hope to allow even young engineers to diagnose issues with the same confidence as veteran specialists.

Satoshi

SatoshiI imagine that many users do not trust AI alone to make important decisions. I believe NSK is in a unique position to provide value through the guarantees and specific recommendations provided by our diagnosticians.

Kunihiko

KunihikoOur goal for the future is to ensure reliability throughout the CMS ecosystem and to expand the range of support that AI can provide.

What has been the biggest challenge in development?

Kunihiko

KunihikoIt is rather difficult for NSK to gather data on machine failures by itself. It’s hard to replicate a machine breakdown in a controlled way, and it is also difficult to collect data on a real-work breakdown after it has already occurred. This makes AI development a challenge. We’ve wanted to install bearings with sensors to collect information on the timing and cause of failures, but costs and other hurdles have not made this feasible. However, B&K Vibro has decades of experience monitoring wind turbine machinery and has accumulated a wealth of failure data. Of course, taking this data and applying it to other industries is a separate challenge!

What has been the most exciting part of working on this project?

Kunihiko

KunihikoI had only worked in Japan and the U.S. before, so it was great to learn about the German work style. I feel that the trial and error of learning how to effectively navigate different styles of communication also improved my approach to finding new processes in development.

Satoshi

SatoshiWe have a truly diverse group of members, including former salespeople, production engineers, and data architects. It was an interesting challenge to have the members of the team share their opinions on equal terms and reach a consensus. Although I believed I was good at coming up with new ideas from scratch on my own, the project helped me rediscover my passion for organizing discussions using frameworks like design thinking*2through trial-and-error.

*2A design approach to identify issues from the user's perspective and adopt creative solutions. Design thinking emphasizes empathy, problem framing, idea generation, prototyping, and verification processes.

Arisa

ArisaWorking on marketing strategy with colleagues from across the globe has also been exciting. I enjoy meeting regularly with B&K Vibro's marketing staff and seeing firsthand how our strategies evolve as our services expand.

What do you find interesting about working in software development at NSK?

Kunihiko

KunihikoNSK is currently working to expand its software expertise, so even if you are a mid-career hire, you will have many opportunities right away, and people across the organization will rely on your skills. Also, software development at NSK is closely linked to actual machines and equipment, so you’ll be able see the tangible results of your work—it’s very rewarding.

Satoshi

SatoshiIn CMS software development, we use the agile approach, first building the minimum required functionality and then improving on it over multiple iterations. It’s a fun and lively approach that’s quite different than the linear nature of the waterfall methodology. All of NSK’s resources are on the table at our discussions as we think about which customers we can reach out to, how we can gather feedback, and what features we can deliver. Since the scope and priorities for each phase are planned out, we can press ahead without worrying about the typical pitfalls of agile development.

Arisa

ArisaSoftware development at NSK requires a deep understanding of the customer's market and their equipment—it’s totally different than working for an IT company, and extremely exciting! Also, since NSK operates globally, we have many chances to work with people from around the world, which has been a unique and rewarding experience.