More than just highest quality

—Tackling value-added design to

exceed automakers' expectations

Automotive Bearing Technology Center

Developing hub unit bearings for a luxury automaker

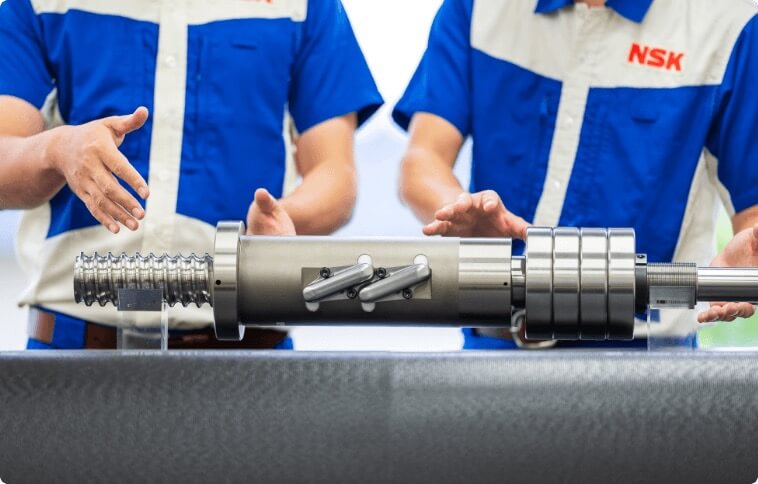

I’ve been in charge of designing hub unit bearings for vehicles since joining NSK as a mid-career hire. Hub unit bearings are used where the wheel attaches to the vehicle axle. They are critical components that must stand up to load and wear with high durability and whose precision has a big impact on fuel efficiency. What’s more, my customer is a premium European brand well-known for its devotion to quality. Our hub unit bearings must clear strict evaluation criteria for low friction (wear), resistance to fretting (surface damage), excellent durability, high sealing performance without grease leakage or contaminant entry, and corrosion-resistant coatings.

It’s thanks to these high expectations that the customer rates us highly and uses NSK products in a majority of their lineup. They have praised us as “a reliable partner who responds quickly to our rigorous requirements with minimal defects in delivered products.”

Of course, this reputation has been cultivated over the years by my seniors and predecessors in technology development and manufacturing. I feel a responsibility to continue making proposals that exceed our customers' expectations and to further expand the use of our high-quality products!

Pursuing new technical endeavors beyond my existing role

When customers are planning new vehicle models for release several years ahead, we study the requested specifications and design hub bearings that can meet these requirements. Rather than simple revisions and additions to existing hub unit bearings, we need to employ new technologies in order to create products that surpass our competitors and the expectations of our customers. It takes 3 or 4 years of prototyping and repeated evaluations to improve quality to a point where we can win a formal order and start mass production. Even for bearings that already mass produced, we diligently pursue value analysis and value engineering to improve quality, optimize materials and processes, and reduce costs while responding to customer requests and concerns.

Outside of this daily work, I’m also involved in the development of low friction technologies. When I'm successful in my work, I am happy in the knowledge that this will not only help me win future orders from my own customers, but also benefit my colleagues working to secure business from other customers. In this way, the team at NSK works together to achieve significant improvements in basic performance across its entire bearing lineup. We are currently working closely with R&D and overseas branches and design teams in pursuing such developments.

The taste of failure makes success even sweeter

Before coming to NSK, I designed actuators used in power plants, but I wanted to be involved in designing products more relevant to my daily life. I decided on NSK since bearings are crucial components in home appliances and vehicles, and the company is a world leader in bearings thanks to its top-class technology. Five years after joining the company, I still get excited when I see vehicles around town that use the hub unit bearings I designed.

At first, I was quite nervous about my new role, but I quickly got more comfortable expressing my opinions. Now, I feel like I am entrusted with some truly important work! Still, it takes courage to tackle high-level technological barriers. Sometimes design and development don’t go as planned, but this pressure keeps things interesting, and even small improvements can eventually lead to success. With this mindset, I try to take failures as a hint in how to correct course. From experience, I know that a deep sense of accomplishment awaits on the other side of the hurdle.

Looking towards future overseas assignments and new fields

Since NSK supplies bearings in all fields across the globe, I hope one day to be involved in applications outside the automotive industry. From the giant bearings in wind turbines to the micro bearings in precision machinery–there are all kinds of designs I’d like to explore. I also hope to have the opportunity to use my skills outside Japan. We work closely with overseas branches on technical projects and have many customers and competitors overseas, so I’d like to take that work a step further with firsthand experience.

But before this, there are still many technical issues in hub bearings that I’m eager to solve! As automakers continue the shift to electric vehicles to pursue carbon neutrality, low-friction hub unit bearings have the potential to directly impact driving range. Just as I’ve done in the past, I’ll work extensively with my colleagues in R&D, manufacturing technology, production, and those overseas to discover new knowledge and communicate my own ideas. Though these actions, I aim to help further NSK's technical advantage and global reputation!

Message to Prospective Employees

NSK has a proud history and world-class technological capabilities. Nevertheless, rather than simply riding on our heritage, our team works hard every day to meet the needs and expectations of our customers while keeping an eye firmly on the future. If you want to improve your current technological skills and broaden your horizons, you will find NSK a rewarding place to work. NSK offers a comfortable work environment with strong support from the people around you and respect for individual work styles. Although I understand from experience that changing jobs can be intimidating, I encourage you to take the first step and reach out to our HR team. I look forward to working with you in the future!

Note: Department names and job titles reflect those at the time of the interview.