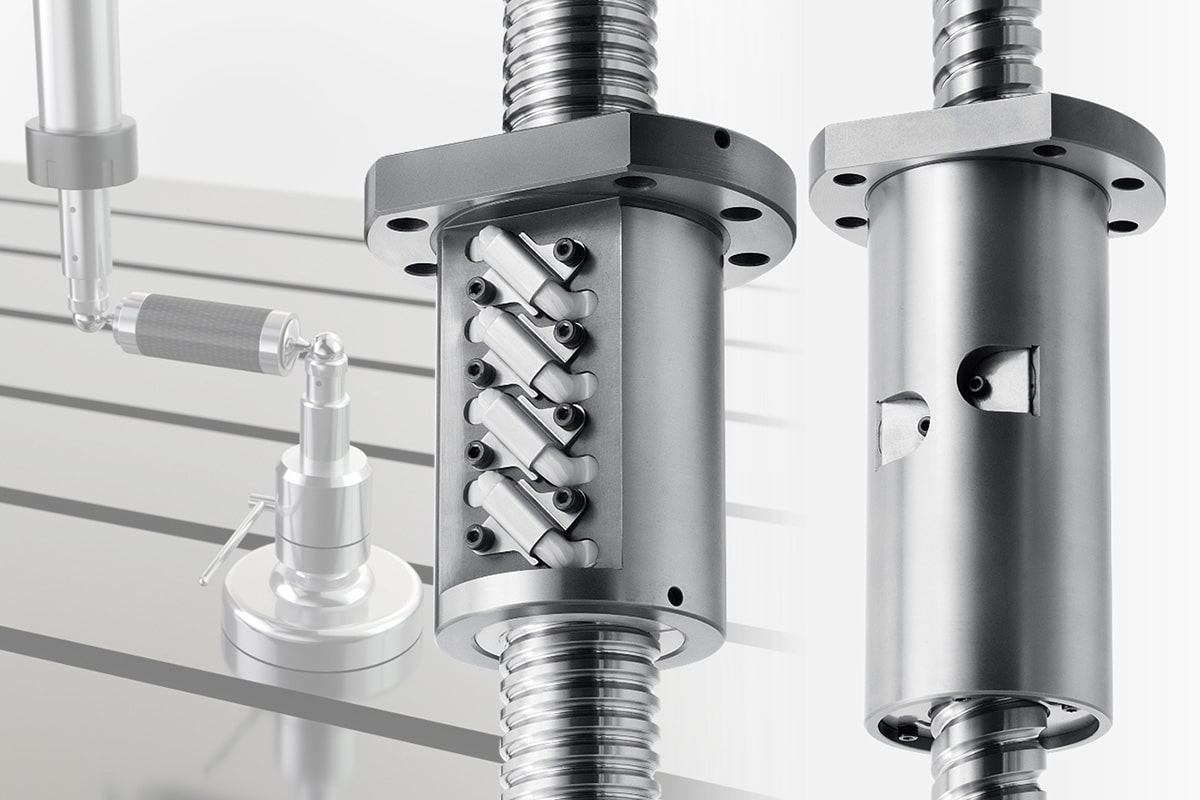

All new NSK technology reduces frictional variation when the ball screw reverses direction of motion. This significantly reduces motion errors called quadrant glitches thereby increasing surface finish quality.

Photo: Ballbar testing. A measurement method used to evaluate the accuracy of machine tool motion.

Stable torque when the ball screw reverses direction nearly eliminates the peak 2 from quadrant glitches.

Up to 20% less dynamic frictional torque allows for better correction of the peak 1.

Mounting dimensions fully interchangeable with conventional products make for an easy upgrade in existing equipment.

Improved surface quality shortens finishing time and saves energy.

Not all products are available in all regions. Please contact your local sales for more information.