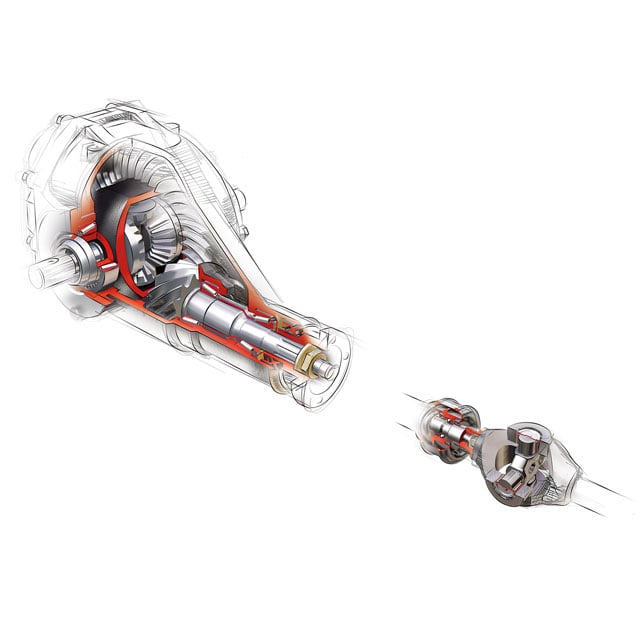

Differential Gear & Propeller Shaft

Overview

In FR vehicles, the engine power is transmitted to the rear differential gear via the propeller shaft. The fact that the center bearing used to support the propeller shaft is located on the vehicle's exterior gives rise to a demand for optimum mud and turbid water resistance in addition to maintaining fast rotational speeds. Due to the large speed-reduction gear ratio of the rear differential gear that conveys engine power to the rear wheels, a large gear-interlocking load affects the bearings that provide support for the pinion gear and the ring gear. In particular, bearings that support the pinion gear require low torque and high durability since these bearings rotate at the same speed as the propeller shaft.