Tackling new frontiers

in heat treatment

to achieve carbon neutrality

Manufacturing Engineering Center

Joining NSK’s team of experts

working to perfect heat

treatment technology

Before joining NSK, I worked in manufacturing engineering for heat treatment processing at an automotive component manufacturer. Although part of my duties involved implementing new heat treatment processes and equipment to improve productivity, in my day-to-day work I primarily handled issues that came up during mass production. This meant that I could only tackle the development of heat treatment technologies in the brief periods when I wasn’t fixing problems on-site. I gradually realized that I wanted to work to solve underlying issues in a purely developmental role, so I made the jump to NSK with its dedicated department tasked with developing heat treatment technologies.

Of course, since I worked in the industry, I knew all about NSK’s excellent technical capabilities and solid reputation. I was curious to find out what kind of heat treatment was used to achieve such precision and high specs. I knew there was still so much to learn, so I decided to move to NSK to take my personal growth to the next stage.

I also chose NSK due to its status as an independent company. This means that the company has control over the direction of its technological developments and aligns these with its business strategy. As the success of our technology development directly affects the company’s competitiveness, we carry a big responsibility, but I find this challenge highly rewarding.

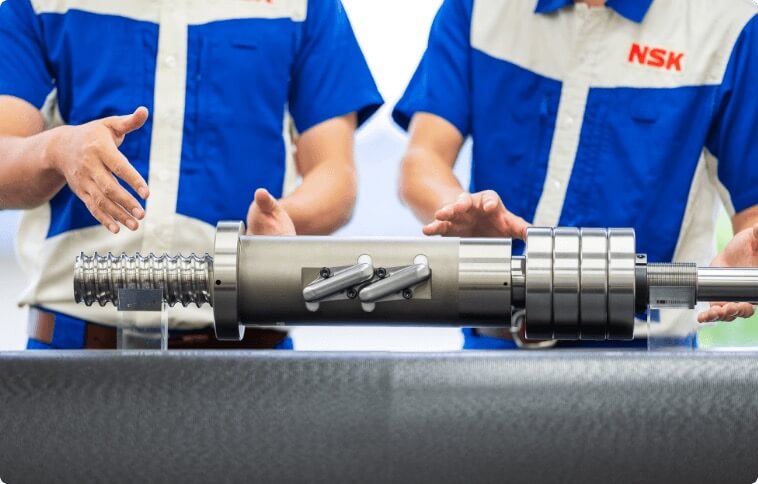

Heat treatment expertise is key for bearing quality

After starting at NSK, I was assigned to the Heat Treatment Group in the Mold Technology Development Department. Finally, I was in my desired role working on the development side of heat treatment for bearings! After molding, metal is heated to a high temperature and undergoes quenching to increase strength, giving it the characteristics required for use in machine components. However, heating alone does not provide the micron-level tolerances we need due to deformations in the steel's shape. While it is important to compensate for heat-induced deformation during molding prior to heating, optimizing the time and temperature of heat treatment processes to match each product can significantly improve quality.

For this reason, we regularly research theories and conduct tests related to heat treatment processes. We make a hypothesis, test it through experiments, and make progress step-by-step as we gather data. It can take several years for the seeds of our work to bear fruit for a single issue; but once they do, we deploy our findings to plants in the form of new heat treatment technologies. After we finally reach this finish line, we often get comments from the plants like “We’ve finally hit our accuracy targets!” and “This technology will transform our operations!” To me, there’s nothing better than hearing those words!

High-frequency induction hardening

is a

game-changer for the environment

Carbon neutrality has been a major theme in heat treatment development in recent years. Current hardening methods require large amounts of energy to build up radiant heat from the burner inside the heating furnace. NSK is striving to achieve carbon neutrality across all its operations, and advances in heat treatment technologies for bearings will have a large impact in these efforts.

Using high-frequency induction hardening reduces energy costs. A coil is wrapped around the steel material, and high-frequency current sent through the coil generates heat in the steel through electromagnetic induction. This method offers higher thermal efficiency than indirect methods that heat the air, yielding huge energy savings over existing methods. While this technology is already in practical use, the sheer variety of bearing shapes, sizes, and materials in NSK’s extensive lineup means there are still a mountain of obstacles to overcome in making heat treatment equipment operator-friendly while delivering optimal heating. By tailoring high-frequency induction heating to NSK’s needs, we hope to implement this technology wherever possible to significantly reduce the company’s energy consumption.

A job that benefits society

and helps

make the SDGs a reality

Environmental initiatives are gaining traction through recent efforts such as the Sustainable Development Goals (SDGs). I think that building awareness of the importance of SDGs and how we affect the global environment starts close to home. I’m working hard to achieve carbon neutrality so that my children can grow up and live full lives in a safe and comfortable world. Additionally, since high-frequency induction hardening equipment doesn’t heat the surrounding environment, operators don’t have to contend with high temperatures while they work, so our efforts are also helping to improve the working environment for our colleagues.

In this way, I can see right before my eyes how the work I’ve been involved in since coming to NSK helps people. Knowing that my work is connected to the happiness of others keeps me highly motivated! I would encourage anyone to consider a career change to NSK, regardless of their technical background. NSK offers a full training program on heat treatment processes, so if you're looking for a role that helps others, we would love to welcome you to our team!

Message to Prospective Employees

At NSK, each member of our team works with confidence and takes pride in their work. In order to provide better products to society, we work as one team in product development, from design to manufacturing, going beyond our own areas of expertise. Having specialists in respective fields working cross-functionally allows us to acquire a wealth of new knowledge and grow on a personal level. To me, this corporate culture is what makes it possible for us to continue to provide products that contribute to society. I know that we have the capacity to flexibly respond to accelerating technological advancements; we'll continue to transform ourselves and go beyond the expectations of our customers. I look forward to meeting new colleagues who have a strong sense of purpose and a desire to make the world a better place.

Note: Department names and job titles reflect those at the time of the interview.